Car Turbocharger Faults: Signs, Causes and Prevention

Automotive turbochargers, despite manufacturer claims of durability, are subject to high loads. Therefore, owners of diesel and petrol turbo engines have to deal with the maintenance of this unit. To identify a problem in time, you need to pay attention to unusual vehicle behaviour.

Signs of a faulty turbocharger:

- loss of power (reduced performance, the engine feels sluggish);

- billowing smoke from the exhaust pipe (blue, black, or white) during acceleration;

- whistling, noise, or grinding sounds are audible when the engine is running;

- sharply increased oil consumption or visible leaks;

- frequent drops in boost pressure.

If such symptoms appear, a thorough check of the turbine is required.

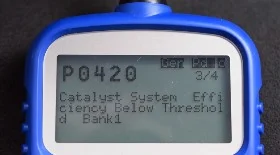

Diagnostics: What the Symptoms Say

- Blue exhaust smoke is a sign of oil burning in the cylinders, entering through the turbocharger or due to worn piston rings. Black smoke indicates an overly rich mixture (air leak in the pressure pipe or lack of boost). White smoke may indicate a blockage in the turbo oil drain.

- The cause of whistling is often an air leak at the junction of the compressor outlet and the engine (leaking hoses). Grinding is a critical symptom indicating the impeller is touching the housing (bearing destruction).

- If the turbo cuts out or does not reach boost, check the geometry control (actuator) and the tightness of the vacuum system.

Most turbocharger breakdowns are caused by three main reasons.

Lack of Oil and Low Pressure

This occurs due to leaks, low oil levels in the sump, or kinked oil pipes. It leads to oil starvation, instant overheating, and wear of the shaft journal and sliding bearings. Parts fail quickly and require replacement.

Oil Contamination

Happens due to delayed oil and filter changes, or fuel/coolant entering the lubricant. Abrasive particles in the oil scratch the shaft and bushings, leading to play. Carbonised oil blocks the lubrication supply channels.

Foreign Object Damage

Objects entering the intake (nuts, sand, pieces of filter) lead to the destruction of the compressor wheel blades. Foreign objects from the engine (fragments of rings, valves, carbon deposits) destroy the hot turbine wheel. In both cases, balance is lost, and the turbo destroys itself.

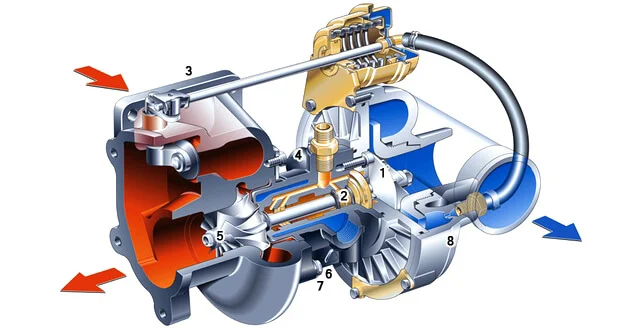

Car engine turbocharger structure: 1. compressor wheel; 2. bearing; 3. actuator; 4. oil feed fitting; 5. rotor; 6. cartridge (CHRA); 7. turbine housing (hot side); 8. compressor housing (cold side).

Can You Repair a Turbo Yourself?

The turbocharger design seems simple, but repair requires high precision. On your own, you can perform a visual diagnosis, remove the turbo, and check for impeller play and hose tightness.

DIY repairs are limited to unit replacement (replacing the cartridge assembly if it is factory balanced, or the entire turbo) and fixing oil and air supply issues.

Turbo Breakdown Prevention

To extend the life of the turbocharger, follow these simple rules:

- Change air filters on time (a clogged filter creates a vacuum and pulls oil out of the turbo).

- Use only high-quality engine oil recommended by the manufacturer.

- Reduce the oil change interval for turbocharged engines to every 7,000–8,000 km.

- Do not switch off the engine immediately after active driving. Let it run at idle for 1–3 minutes to allow the turbo to cool down. This prevents oil coking in the bearings (unless a turbo timer is installed).

- Regularly check the intake and exhaust systems for leaks.

Was this article useful?

Your feedback helps us improve our content.

Related Materials

Discussion (0)

No comments yet!