Blown Head Gasket — How to Tell?

A blown head gasket leads to unpleasant consequences such as engine overheating, poor heater performance, exhaust gases escaping from under the bonnet, emulsion forming in the engine oil, white smoke from the exhaust pipe, and other issues. If any of the symptoms listed above appear, it is necessary to check the cylinder head gasket. There are several ways to do this. Below, we will look at why head gaskets fail, the consequences, and what to do if this misfortune happens to your car's engine.

Signs that the head gasket has blown

The task of the cylinder head gasket is to ensure a seal and prevent gases from the cylinders from escaping back up into the engine bay, as well as to prevent coolant, engine oil, and fuel from mixing. When a head gasket is blown, the seal of the block is compromised. The following signs will alert the car owner to this:

Signs of head gasket failure

- Exhaust gases escaping from under the cylinder head. This is the simplest and most obvious sign. When the gasket burns through, it starts to let exhaust gases out into the engine bay. This will be visually apparent and also audible — loud noises will be heard from under the bonnet. However, if the leak is small, look for other signs.

- Blow-by between cylinders. The external signs will resemble those of a misfiring engine. The fuel mixture from one cylinder mixes with the exhaust gases in another. Usually, in this case, the engine is difficult to start, but after warming up, it continues to run stably at higher revs. To identify the fault, a compression test is required. If the mentioned mixing occurs, the compression values in different cylinders will vary significantly.

Emulsion under the expansion tank cap

- Exhaust gases entering the coolant. If the head gasket is blown, exhaust gases from the cylinder block can enter the cooling system. In this case, simply unscrew the radiator or expansion tank cap. If a large amount of gas is entering the system, the bubbling will be very active. If there is only a little gas, makeshift means are used for diagnosis — plastic bags, balloons, a condom, or special chemical testers.

- Coolant entering one of the cylinders. Typically, this happens due to a gasket rupture between the cooling jacket channel and the combustion chamber. Often, this results in white smoke appearing from the exhaust pipe, even in warm weather. Meanwhile, the coolant level in the tank drops. The more antifreeze that gets into the cylinders, the more white steam will come out of the exhaust pipe.

- Oil leaking externally from under the cylinder head. A rupture of the gasket's outer shell occurs. In this case, oil streaks can be seen around the junction of the cylinder head and the block. However, the causes could lie elsewhere (for example, a leak from the rocker cover).

Foam in the expansion tank

- Significant and rapid rise in engine temperature. Hot exhaust gases enter the cooling system, causing air locks and preventing it from coping with its tasks. In this case, in addition to replacing the gasket, it is also necessary to flush the system. You can read separately about how to do this and which products to use.

- Mixing of oil and coolant. Coolant can get into the sump and mix with the oil. This is critical for the engine: lubricating properties are lost, leading to wear of the bearings and the piston group. This fault can be diagnosed by the presence of emulsion (so-called "mayonnaise") on the dipstick or under the oil filler cap.

Wet spark plugs

- Poor heater performance. When the head gasket burns through, gases in the cooling "jacket" create air locks. As a result, the heater matrix becomes air-bound, and its efficiency decreases.

- Increased pressure in radiator hoses. The hoses become very hard to the touch ("stone-like"); it is impossible to squeeze them with your fingers.

- Appearance of carbon deposits or moisture on spark plugs. Plugs may be wet due to the presence of coolant in the cylinders.

A clear sign of engine overheating is the presence of condensation on its surface. This is also an indirect sign of a burnt head gasket or a crack in the cylinder block. First and foremost, perform a computer diagnostic of the engine for misfires.

Coolant in the cylinder

Let's dwell once more on the mixing of coolant and oil. If emulsion has appeared, the repair will not be limited to just replacing the head gasket. It is imperative to flush the lubrication system, as antifreeze is chemically aggressive towards crankshaft bearings.

Why does the head gasket blow?

In most cases, the cause is simple overheating. Because of this, the mating surface of the cylinder head can become warped, compromising the tight fit of the gasket. Aluminium heads are more prone to deformation than cast iron ones.

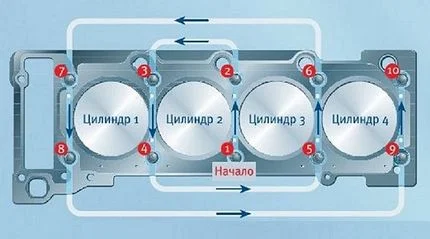

Head bolt tightening sequence on classic cars

Also, due to overheating, the gasket can physically burn out. This is especially true for older asbestos gaskets.

Another reason is incorrect bolt torque. Both insufficient and excessive force are bad. In the first instance, gases will break through; in the second, you can crush the gasket or stretch the bolts. Bolts must be tightened strictly using a torque wrench, following the sequence (pattern) and torque settings specified in the vehicle manual.

Typically, tightening starts from the central bolts outwards in a spiral or criss-cross pattern. Tightening occurs in several stages with pauses for "settling".

And the most obvious reason is the poor quality of the part itself or its natural wear and tear (everything has its service life).

Examples of head gasket failure points

Sometimes causes can also include detonation or pre-ignition, creating shock loads. Often the gasket burns out along the cylinder rim.

How to know if the head gasket is blown

You can determine if the head gasket is blown yourself. The diagnosis is not difficult and is accessible even to an inexperienced driver.

Steps for checking:

- Visually inspect the junction of the cylinder head and the block for smoke or leaks.

- Inspect the oil filler cap. If there is an emulsion the colour of "coffee with milk" on the inside, coolant has entered the oil.

White smoke from the exhaust pipe

- Ensure that thick white steam is not coming from the exhaust pipe. A sweetish smell from the exhaust indicates burning antifreeze.

- Check for gases in the cooling system. Open the expansion tank cap (carefully, on a cooled engine!) and see if there are air bubbles smelling of exhaust fumes.

- Use a chemical tester. The most modern method. A special flask with indicator fluid is placed on the radiator neck. If CO2 (exhaust gas) is present in the system, the fluid changes colour (usually from blue to yellow or green).

How to check the head gasket using a condom or balloon

An old-school method if you don't have chemicals at hand. A condom (or a sturdy balloon) is placed over the neck of the expansion tank. It must fit tightly. Start the engine and let it run (sometimes you need to raise the revs slightly to 2000-3000). If the item inflates quickly, it means gases are breaking through into the cooling system, and the gasket is blown.

Checking the head gasket with a condom

The condom test

Checking the gasket with a bottle

This method is often used on trucks or cars with an overflow pipe on the expansion tank. The end of the tube (breather) is lowered into a bottle of water. With the engine running, air bubbles should not come from the tube. If there is a constant chain of bubbles, the gasket is not airtight.

Checking head gasket on trucks

Checking with a bottle

What to do if the head gasket blows

You cannot drive with a blown gasket. Cautious driving to a service station is only permissible while monitoring the temperature. Coolant entering the oil will kill the engine in a few dozen kilometres, and hydrolock (if a large amount of liquid enters the cylinder) will destroy the piston assembly instantly.

When repairing, consider the following:

- Cylinder Head Bolts. On most modern cars, these are single-use (Torque-to-Yield). When removing the head, they must be replaced with new ones. Using old bolts will not ensure the required clamping force.

- Surface Grinding. The cylinder head must be checked for warping.

A straight edge and feeler gauges are used to check the surface plane. The straight edge is applied diagonally, lengthwise, and crosswise. Acceptable warping usually does not exceed 0.05...0.1 mm (check your car manual for exact figures). If a 0.1 mm feeler gauge fits under the straight edge, the head needs to be taken for skimming (resurfacing). Ignoring this rule will lead to the new gasket burning out in a couple of days. If the skimming was deep, you need to select a repair gasket of increased thickness.

Checking the cylinder head surface

After repair, monitor fluid levels and temperature. Avoid maximum loads for the first few hundred kilometres.

Which gasket material is better

Gaskets made of different materials

The choice between metal and composite (paronite) depends on the manufacturer's recommendations and the condition of the surfaces.

Metal (MLS) gaskets are more durable and withstand high pressure (relevant for turbo engines), but they are very demanding regarding surface quality. If the block or head has pitting or corrosion, a metal gasket may not seal properly.

Soft (composite, fibre) gaskets are more forgiving of irregularities but have a shorter service life and tolerate overheating worse. If you are not tuning the engine, install an equivalent to what was fitted at the factory, from a proven brand (Elring, Victor Reinz, or genuine).

Conclusion

If you discover symptoms of a blowout, do not delay the repair. The longer you drive with emulsion in the oil or gases in the coolant, the more expensive the engine restoration will be. Control the tightening torques and be sure to check the cylinder head plane before assembly.

Was this article useful?

Your feedback helps us improve our content.

Related Materials

Discussion (0)

No comments yet!