How to Check Car Suspension Springs

The question of how to check a suspension spring usually only interests car owners when the vehicle begins to "sag" even under a light load. However, diagnosing the condition of the springs should be done at the first sign of wear. The simplest check can be carried out in a garage or on a driveway using a standard tape measure and a visual inspection. There is no need to dismantle the suspension for an initial diagnosis.

Signs of Suspension Spring Failure

The following symptoms indicate a need to check the suspension springs:

- Body list (leaning). It is visible to the naked eye that one side of the car has "sagged" lower than the other when unladen (without cargo or passengers). You should compare the height of the wheel arch above the wheel on the same axle (left and right). A list indicates that a spring has either sagged or snapped.

- Metallic clanking when driving over bumps. This is a clear sign of a broken spring (usually the end coil snaps off). The noise may be audible even on small uneven surfaces. In this case, you should also inspect the spring seat and the strut top mount.

- Low ride height (bottoming out). Even with a minor load, the wheels begin to rub against the arch liners, and mudflaps touch the road. This is dangerous: the suspension stops absorbing impacts effectively, leading to accelerated wear of tyres and shock absorbers.

- Suspension bottoming out and vibration. The spring stops functioning correctly, and the car receives harsh impacts when driving over potholes because the shock absorber compresses to its limit.

- Excessive body roll in corners and nose-diving when braking.

If these signs appear, perform a visual inspection and measure the ride height (ground clearance).

Causes of Spring Failure

There are several reasons why rear and front springs fail:

- Metal fatigue. Occurs naturally over time. The metal "settles", and the spring becomes shorter and softer.

- Surface damage to the coil. Frequent suspension compression to the bump stops can cause the coils to touch and rub against each other. Stones that damage the protective coating are also harmful.

- Overloading the vehicle. Regular driving with maximum load or towing a trailer quickly "settles" the springs.

- Corrosion. The most common cause of failure. As soon as the paint or polymer coating is damaged, rusting begins. Corrosion creates stress concentrators, and the spring snaps at that point. If rust eats away just 0.15 mm of a 10 mm bar, the part's strength drops significantly.

- Installation of incorrect parts. Wrong stiffness selection or a manufacturing defect.

How to Check a Suspension Spring

You do not need to remove the spring for a basic check. Dismantling is only required for a detailed defect analysis or replacement. The main diagnostic methods are visual inspection and measuring ride height.

Visual Inspection

Drive the car onto an inspection pit or ramp (or jack it up and remove the wheel). Clean the spring of dirt with a stiff brush and inspect it carefully:

- Integrity of the coils. The very top or bottom coils often snap. Check if they are seated evenly in the cups.

- Signs of coil contact. If rub marks are visible between the coils, the spring is too soft or has sagged.

- Corrosion. Deep rust and peeling paint are reasons to prepare for replacement.

Measuring Height (Ride Height)

This is the most objective method for checking spring "fatigue". The car must be on a level, horizontal surface without a load.

The simplest method for most cars is to measure the distance with a tape measure from the centre of the wheel hub to the edge of the wing (wheel arch) vertically. This eliminates the influence of tyre pressure on the result.

- Compare the readings for the left and right sides. The difference should not exceed 10–15 mm. If the difference is greater, the spring with the lower value has sagged or snapped.

- Compare the figures obtained with factory tolerances (if available in the manual) or with measurements on a known good vehicle of the same model.

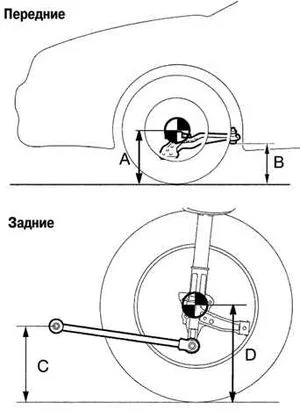

Below is an example of diagnostics using the factory method for a Toyota Camry, where clearance is measured relative to suspension control points:

- A — distance from the ground to the centre of the front wheel;

- B — distance from the ground to the lower arm bolt;

- D — distance from the ground to the centre of the rear wheel;

- C — distance from the ground to the trailing arm bolt.

The difference is calculated (A-B and D-C) and compared with the standard:

| Wheels (Axle) | Minimum height, mm |

|---|---|

| Engine 1MZ-FE (3.0 L) | |

| Front | A — B: 116 |

| Rear | D — C: 40 |

| Engine 1AZ-FE (2.0 L), 2AZ-FE (2.4 L), R15 | |

| Front | A — B: 115 |

| Rear | D — C: 40 |

| Any engine, R16 wheels and larger | |

| Front | A — B: 101 |

| Rear | D — C: 25 |

If the values obtained are lower than those in the table, the springs have sagged and require replacement.

When to Replace Springs

Springs should be replaced in the following cases:

- Broken coil. Driving the car is prohibited; immediate replacement is required (preferably as a pair on the axle).

- Significant sagging. If the ride height has decreased to the point where the suspension bottoms out, or the difference in height between sides exceeds the tolerance.

- Severe corrosion. If the metal is pitted with rust, the spring could snap at any moment while driving.

- Together with shock absorbers. It is recommended to change springs every second shock absorber replacement (approximately every 80,000–100,000 km). Old, soft springs will quickly destroy new shock absorbers as they will not dampen oscillations properly.

If the springs have only sagged slightly and the metal is in good condition, some car owners use spacers to increase ride height. This is a budget solution, but it is temporary and can alter the suspension geometry, negatively affecting handling.

Conclusion

Checking suspension springs is a procedure accessible to everyone. The main thing is to keep an eye on the car's stance: if it sits crookedly or too low, grab a tape measure and check the height from the wheel centre to the arch. Driving on broken springs is dangerous: a sharp fragment of the coil can damage a tyre or brake hose.

Was this article useful?

Your feedback helps us improve our content.

Discussion (0)

No comments yet!