The error p0443 indicates a defect in the evaporative emission system valve circuit (the diagnostic equipment will show: Evaporative System Purge Control Valve Circuit Malfunction). More often the error code p0443 occurs in cars with considerable mileage (age), caused by clogging of pipes or the valve itself (its filter). The error itself is not critical and the car can be used.

But at the slightest opportunity it is better to get rid of it, moreover it's not complicated at all. In most cases, you will only need to clean the elements of the gasoline vapor recovery system.

What is EVAP

Before we move on to the description of error p0443, it makes sense to briefly dwell on the description of the operation of the Evaporative Emission Control (or shorter — EVAP). Its main task is to prevent the escape of petrol vapors into the atmosphere. These same vapors are formed in the fuel tank at high ambient temperatures, or in rarer cases, when the atmospheric pressure drops. The gasoline vapors accumulate in the system, and when the engine starts, they are vented into the intake manifold and burned in the engine along with the fuel-air mixture. EVAP is used in almost all engines of modern vehicles.

The gasoline vapor recovery system includes an adsorber (filled with charcoal pellets and actually designed to accumulate gasoline vapors in itself), an adsorber purge solenoid valve, and connecting pipes. Error code p0443 just indicates a failure of the mentioned solenoid valve, so it is sometimes called a fuel vapor valve error.

In engines that have a turbine, the system is augmented with a two-way valve, which is designed to direct fuel vapor from purging the adsorber into the intake manifold (if there is no boost pressure) or to the compressor intake (if there is boost pressure). A two-way valve is needed in the system because turbo engines do not create vacuum in the intake manifold.

A feature of the gasoline vapor recovery system is the fact that it has a built-in self-diagnostic module. This means that when you start the engine, this system is checked automatically for proper operation, in particular for leaks and the correct operation of its individual elements. This is done for environmental reasons, in order to minimize the probability of gasoline vapors entering the atmosphere. In turn, this is dictated by the strict legislation in force in this regard in the European Union and some other countries, including the United States.

External signs of error P0443

EVAP valve

In most cases, there are no external signs of error p0443, except for an activated Check Engine warning light on the dashboard. In more rare cases, there may be a petrol smell in the passenger compartment caused by a significant amount of petrol vapour released from the car's fuel system into the atmosphere or its ventilation system.

Unstable engine operation at idle, engine “hunting” and even complete stopping of the engine is also possible. While driving, you may observe decreased dynamic characteristics of the vehicle, it accelerates poorly, thrust is low. However, such symptoms may indicate a variety of other malfunctions, so additional diagnostics is required to identify the cause.

Occasionally, there are cases when the p0443 error occurs when the air conditioner or climate control system is on. The fact is that when these systems are activated, the engine begins to consume more fuel, respectively, there are more gasoline vapors in the system. And if their value exceeds the permissible norm — it leads to the conditions of error formation under the condition that the system purging electromagnetic valve is in the emergency state.

Conditions of formation

Error code P0443 is generated when the ignition key is turned in the ON position, i.e. the ignition is on, but the engine has not been started and the ECU diagnoses an open or short circuit of the electric winding of the valve of fuel vapor recovery system. At the same time the «check» signal lamp is also activated.

Also, some vehicles have additional requirements for generating a p0443 error code. For example, for the popular Chevrolet Captiva these conditions are the turned on ignition, as well as the voltage on the battery and the whole electrical system in the range from 11 to 18 volts DC. Besides, ECU diagnoses error after 6 seconds of observing the mentioned conditions. Other cars may have different values, but the logic remains the same.

Possible causes of error code p0443

There are a number of typical causes of the so-called absorber error, as p0443 is sometimes called. Among them:

- Complete or partial failure of the electro-pneumovalve of the gasoline vapor recovery system.

- Breakage or short circuit (to "+" or «ground») of wire, connecting conclusions of electro-pneumovalve and electronic engine control unit (ECU).

- Breakage (or isolation damage) of wire between ECU and “minus", which is responsible for signal transmission to electromagnetic valve.

Valve circuit failure

- Breakage (or isolation damage) of a wire between the main relay and the terminal on the electromagnetic valve of fuel vapor recovery system.

- Mechanical damage to the purge valve. For example, it is stuck in fully open or fully closed position.

- Damage in the connectors, the so-called «plugs». They will be different for each car model, it is necessary to check those contacts, which are responsible for controlling both the gasoline vapor recovery system in general, and the control of its solenoid valve in particular.

- Incorrect operation of ECU. This is quite a rare cause, but there are cases when, after its reprogramming or mechanical damage (e.g., damage to the electronic track), the so-called «glitches» took place. However, in this case, as a rule, there is not one, but several errors, often unrelated to each other.

However, most often the errors connected with incorrect operation of the fuel vapor recovery system (including 0443) are caused by clogging of the filter and tubes or other elements included in the mentioned system. For example, a common cause is that the foam in the adsorber rots and crumbles over time, which causes the carbon to go into the system, clogging it. Including the clogging of the valve, as a consequence of which it ceases to work correctly, causing the corresponding errors. Rotting occurs for trivial reasons — old age, constant wetting from condensation, temperature fluctuations and so on. Often with a clogged EVAP valve, when the front windows are open, you can smell the obvious smell of gasoline in the cabin. It is especially crucial for a warm season.

There are cases when the cause of dtc P0443 is the absence of a fuse in the circuit of Evaporative System Purge Control Valve. Another possibility is the use of a fuse with a lower than necessary tripping current rating. For example, on the popular Chevrolet Aveo, a 10 amp fuse instead of the proper 15 amps was observed when the appropriate fuse was installed. Its replacement solved the problem.

The cause of error p0443 can also be depressurization of the fuel tank lid (or hose system). For example, the sealing rubber on its lid has worn out over time and does not hold the vacuum. To check it, just listen if there is a hissing sound when the car owner unscrews the gas tank lid. If there is a sound, then most likely the system is airtight. If there is no such sound, there is a risk that it lets air in, and this can be a direct cause of error code p0443 in the ECU.

Fixing error p0443

Methods of fixing code p0443 depend on the reasons that caused it. First of all it is necessary to check whether the formation of error P0443 is a so-called «glitch». For this purpose, it is necessary to delete information about the error from the ECU memory programmatically or mechanically. There are several ways to do it. The first, more «civilized» way is to delete the mentioned information with the help of a computer and corresponding software. However, you need to have a computer or a smartphone and software for that.

The other method is simpler. To do it you just need to disconnect the minus terminal of the battery for 5...10 seconds and then put it back. After this, the electronic control unit will restart and diagnose all systems of the car again. If there was a false alarm, then the error information will not repeat. If, however, the formation conditions are present, you need to perform further diagnostics.

To do so, perform one or more of the following actions:

EVAP valve replacement

- Check the condition of the adsorber. To do this, remove the EVAP solenoid valve and see if there is charcoal in its housing. If it does, you need to replace the foam separator of the adsorber. If it is very corroded and/or its housing is damaged, you should also consider replacing the adsorber completely.

- Check the operation of the electric vacuum purge valve from the carbon adsorber. This can be done in two ways. The first — with the help of a special diagnostic device, so it is suitable, rather, for car service workers. To do this, you need to disconnect the vacuum hose of the purge valve from the adsorber, start the engine (previously set the neutral speed and engage the parking brake) and connect the electronic diagnostic device. Then, depending on the software used on it, see the working characteristics of electric valve. Manual check is much easier. To do this, you only need to put your finger to the disconnected hose and check whether air is sucked into it or not. When it is working, it should be sucking in air, if it is not, then most likely the solenoid valve is out of order and additional diagnostics is needed. When the valve is off, air is also not being sucked in.

- If the check found that the valve itself is in working order, it is necessary to perform a revision of its wiring. To do this, first of all disconnect the valve connector (VSV). Next, use a multimeter to measure the voltage applied to the solenoid valve when the ignition is on. This value should be between 11...14 volts for standard passenger cars, which are designed for 12 volts electrical system voltage.

- To check the integrity of the wire connecting the ECU and the solenoid valve, you must disconnect them from both sides, that is, disconnect the connectors. Then using the same multimeter (but switched to «test» mode or resistance value measurement mode) check the continuity of the wire. The normal value of the insulation resistance should be between 1 ohm and 10 kOhm. If the measured resistance value is out of this range, then the wire is broken or the insulation is damaged. In any case, you need to look into it in detail and visually check the condition of the wire. If you can't do it, just replace the wire or the whole harness with a new one.

- Check the condition of the wire between the solenoid valve and the integrated relay or fuse (this step may vary from model to model as this circuit may be implemented differently). The steps are similar to the previous point. It is necessary to disconnect the wire from both ends and measure its insulation resistance value. The range here will be similar — from 1 Ohm to 10 kOhm. If the value is more or less — it means that the wire is damaged.

Service technicians can check the fuel vapor recovery system purge valve with the above-mentioned diagnostic device and software. Thus, with the ignition on and the engine off, connect the device to the ECU and use the software to give commands to the mentioned valve. At the same time, you should clearly hear clicks characteristic of its operation. In particular, it is necessary to give a command for its opening at 50%. When this value is increased, the cycle speed of the valve should increase, and when the value is decreased, it should decrease. When the value reaches 0%, the valve should stop clicking.

If the problem is mechanical damage to the valve, an attempt can be made to «resuscitate» the valve. The standard design of this valve implies a solenoid coil and a needle with a spring, which opens/closes the valve. Over time, the spring can get «old» and stop to produce the necessary force. Or there will be an intercircuit in the coil. In either case, the valve will not work properly. An attempt can be made to replace the spring and/or clean the mechanical valve actuator. However, in most cases of this malfunction, the service technicians (car owners) simply replace the adsorber valve with a new one.

Additional errors

Often the adsorber error is accompanied by other, parallel errors, which indicate problems with adjacent elements of the system. Thus, frequent «satellites» of the above-mentioned failure are errors with codes:

P0444. This error indicates that there is a short circuit to the power supply or an open circuit in the control circuit of the purge valve. Also to generate error code p0444, the following mandatory conditions must be met (they may differ for different car models, the popular Hyundai Solaris is taken as an example):

- intact (not torn or damaged) electrical wiring, particularly from ECU to EVAP solenoid valve;

- value of constant voltage on the battery and in the whole electrical system of the machine is within the range of 10.7 to 16 volts;

- long diagnostic time;

- activation of Check Engine control lamp on the instrument panel is performed after three driving cycles.

In the mentioned Hyundai Solaris, the resistance value of the EVAP valve winding is exactly 16 ohms at a temperature of +20°C.

P0447. The error code indicates an open (broken) circuit in the control circuit of the fuel vapor recovery valve. As a rule, the reason for this error formation is «rotting» of control wiring going to the electromagnetic valve. This problem often occurs on cars where the valve is located in the rear of the body, for example, near one of the rear wheels. In this case the wiring is affected by moisture, dirt, reagents from the road surface. All of this over time can damage the protective insulation of the wiring and, as a consequence, cause an error with the mentioned code. As a repair, we can only recommend replacing the wiring, or maybe the entire valve.

Conclusion

Error code p0443 is not critical, and when it occurs, the car can be used without worrying about its technical condition. However, the faults that caused it still have a negative impact on the environment, and in critical cases can lead to poisoning by petrol vapors of the driver or passengers. Also, a large amount of vaporized gasoline in an enclosed area can lead to increased explosion hazards and/or fire. Therefore, if possible, it is better to get rid of error p0443 by correcting the faults that caused the conditions of its formation.

-

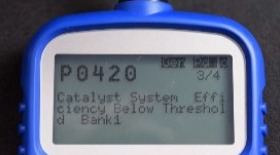

Error code P0420: signs, causes and fixing the catalyst low efficiency

-

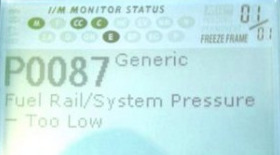

Code P0087

-

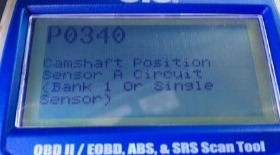

P0340 - camshaft sensor error

-

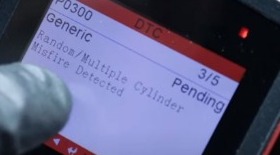

P0300 - ignition misfire error. Causes, consequences, fixing

-

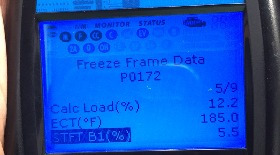

P0172: System Too Rich Error. р0172 System Too Rich Diagnostic Trouble Code

-

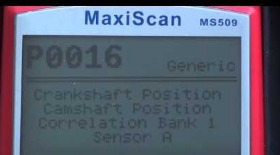

P0016 error of mismatch of the signals of the sensors of the crankshaft and camshaft. Causes and elimination

-

P0141: error code of the oxygen sensor heating circuit B1S2

-

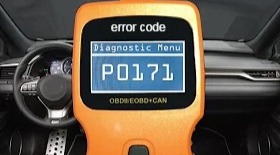

P0171: error code “lean mixture”. The reasons and ways of fixing the error р0171

-

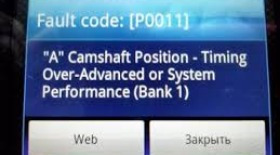

P0011: error of the camshaft position (synchronization or performance of the system)

Error code P0420: signs, causes and fixing the catalyst low efficiency

Error code P0420: signs, causes and fixing the catalyst low efficiency

Code P0087

Code P0087

P0340 - camshaft sensor error

P0340 - camshaft sensor error

P0300 - ignition misfire error. Causes, consequences, fixing

P0300 - ignition misfire error. Causes, consequences, fixing

P0172: System Too Rich Error. р0172 System Too Rich Diagnostic Trouble Code

P0172: System Too Rich Error. р0172 System Too Rich Diagnostic Trouble Code

P0016 error of mismatch of the signals of the sensors of the crankshaft and camshaft. Causes and elimination

P0016 error of mismatch of the signals of the sensors of the crankshaft and camshaft. Causes and elimination

P0141: error code of the oxygen sensor heating circuit B1S2

P0141: error code of the oxygen sensor heating circuit B1S2

P0171: error code “lean mixture”. The reasons and ways of fixing the error р0171

P0171: error code “lean mixture”. The reasons and ways of fixing the error р0171

P0011: error of the camshaft position (synchronization or performance of the system)

P0011: error of the camshaft position (synchronization or performance of the system)