Starter Motor Faults

When the starter motor doesn't work or operates intermittently, starting the engine becomes problematic and sometimes impossible. However, before looking for the reasons why the starter won't turn over, remember that this unit works in tandem with other systems in the vehicle's general starting and charging circuit (Battery – Ignition Control Mechanism – Starter). Therefore, faults can be mechanical or electrical, each having distinct features. Each cause of failure is determined by characteristic symptoms or through testing.

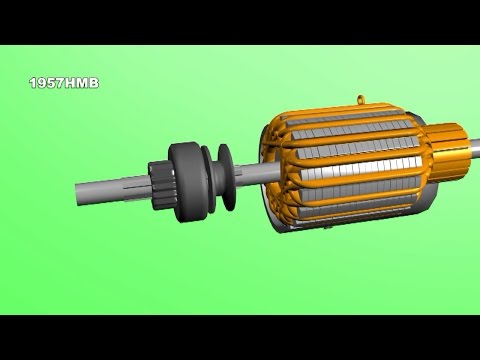

Starter Motor Principle and Construction

A starter is an electromechanical device that starts the engine by creating the initial torque at the crankshaft with the necessary RPM to create compression for igniting the fuel mixture.

If the electrical side is in order and the circuit is undamaged, you should remove the part for disassembly and detailed inspection to reveal defects. But before doing this, it is necessary to study the construction and operating principle of the automotive starter.

Car starter construction: 1. front cover; 2. bendix (pinion drive); 3. reduction gear; 4. armature; 5. stator housing assembly; 6. fork; 7. solenoid relay; 8. brush holder; 9. brushes; 10. rear cover.

When the key is turned to start the engine, the following processes occur:

How the starter works

- The ignition lock contacts close, and power is fed through the starter relay to the solenoid relay windings (pull-in and hold-in coils).

- The magnetic field in the windings pulls the armature inside the housing with force (compressing the return spring).

- It then begins to push the rod with the contact plate, which closes the solenoid contacts, causing the starter motor to begin rotating. Simultaneously, the fork extends the bendix (pinion gear) forward from the armature, engaging its gear with the engine flywheel. This subsequently leads to starting.

- At the moment the flywheel begins to rotate faster than the pinion gear, the overrunning clutch prevents torque transmission, and the lever retracts the bendix, returning it to its position thanks to the return spring.

The key in the ignition returns to its original position, and voltage at the control terminal disappears. Based on this scheme, assumptions can be made about possible malfunctions at the corresponding stages.

Electrical Causes of Faults

When the starter does not turn the engine or turns it slowly, with insufficient power for starting, the first step is to check the electrical circuit, starting from the battery:

- The battery must be well charged;

- Earth contacts (ground) must be secure and tight;

- The wire from the solenoid terminal must be intact and have good contact;

- The main cable between the battery and starter must be undamaged with a solid connection;

- The ignition switch contact group must be functioning correctly.

Pay attention to these faults when the key is turned in the ignition, but the solenoid does not engage, and the armature does not rotate. This could indicate a break in the solenoid winding, a short between turns, or a short to earth.

Slow rotation of the flywheel also indicates electrical problems with the starter.

When there are no visible external causes, the component should be removed for inspection, as the commutator may be burnt or its plates shorted. However, among possible causes, the main one remains worn or sticking brushes.

Since typical starter faults are:

- Brushes not making tight contact with the commutator;

- Solenoid relay failure;

- Wear on the armature commutator.

Sometimes, the starter solenoid can burn out. There are 3 reasons why this happens:

- degradation of relay materials;

- burning of the contact plates (commonly known as the contacts);

- burnt winding.

Often, such problems arise when water enters the housing. Therefore, you will have to disassemble the solenoid and check the condition of the contact plates and subsequently the winding. However, most often, a relay problem is solved by replacing it.

Mechanical Faults

One can speak of mechanical faults if the starter works, but the engine does not start because the crankshaft is not rotating.

Parts subject to inspection:

- overrunning clutch lever;

- clutch ring;

- buffer spring;

- flywheel ring gear.

One reason why the starter doesn't turn the crankshaft

With a spinning starter, engine starting may not occur if:

- the clutch is slipping;

- the disengagement lever has failed or popped off the pivot;

- the clutch drive ring is worn, or the buffer spring is failing.

If a grinding noise is heard during starting, such symptoms may indicate wear on the flywheel ring gear teeth. In this case, check the gear travel adjustment and the condition of the buffer spring.

If you hear atypical noise during starter operation, inspect it from an inspection pit and under the bonnet, as one of the following mechanical starter faults may have occurred:

- bearing bushes and armature shaft journals are worn;

- starter mounting bolts have loosened;

- teeth are damaged;

- pole fixings inside the starter have loosened, causing the armature to strike them.

Burnt contact plates are a characteristic reason why the car cannot be started in the morning. Quite often, if the plates are burnt, the starter does not turn on a cold engine. If you remove it and test the solenoid separately, everything may work, but after installation, it continues to click and does not work. The remedy is as follows:

Burnt contact plates

- desolder the solenoid contacts;

- use a screwdriver to un-crimp and open the housing;

- clean the contact plates;

- turn the wide plate on the rod and install it reverse side up.

Besides problems arising at the starting stage, they also happen after starting. A typical situation is when the starter does not disengage and continues to spin. The culprit for this starter problem could be:

- A jammed drive lever or drive on the armature shaft.

- The solenoid relay has jammed.

- Contacts on the solenoid have fused together.

- The ignition switch return spring or the freewheel clutch spring has worn out.

If you haven't encountered the above breakdowns yet, but the starter has begun to behave unusually during engine start, pay attention to symptoms that may indicate imminent failure:

The starter fault was hidden in the brush assembly

- The starter only begins to turn after several attempts at turning the key. This symptom indicates burnt contacts in the solenoid.

- After starting, it disengages late. Wear has appeared on the pinion gear teeth or the flywheel ring gear.

- The starter rotates with great difficulty, even though the battery is charged. This behaviour likely indicates worn brushes or bearing wear.

How to Identify a Starter Fault

You can quickly identify a starter malfunction by characteristic symptoms. The table below presents the most basic ones and indicates possible causes of failure.

| Symptom | Fault | Cause |

|---|---|---|

| Starter spins (whirs) but engine doesn't turn | Planetary gear failure | Water entered and washed out the grease. As a result, the bushings and planetary gear teeth wore out. Incorrect adjustment of diesel fuel equipment can lead to engine kickback of the ring gear against the bendix drive gear. |

| Bendix failure | Bendix springs have weakened | |

| Starter clicks | Lost earth connection on housing | Oxidation or break in the earth lead |

| Insufficient starting current | Battery is discharged or shorted | |

| Worn brushes | Natural mechanical wear, brush replacement needed | |

| Solenoid relay failure | Winding or contact plates burnt out | |

| Armature failure | Rotor laminations worn, short to earth on armature | |

| Starter turns heavily (slowly) | Rotor bushings worn | Water ingress, grease washed out |

| Brush assembly shorted to earth | Water ingress, brush assembly wear | |

| Stator winding shorted to earth | Water ingress, stator winding insulation destroyed | |

| Armature winding shorted | Water ingress, armature winding insulation damaged | |

| Metal grinding noise heard when starting | Bendix bushing worn | Water ingress washed out grease, or natural component wear occurred |

| Scoring on flywheel ring gear | ||

| Bendix freewheel shaft bushing worn | ||

| Starter works when cold, but only clicks when hot | Solenoid relay fault | Solenoid core stuck |

| Brush assembly springs weakened | Springs heated up due to prolonged use and starter overheating | |

| Worn bushings | Grease washed out | |

| Reduced contact area of plates | Burning of contact plates | |

| Loss of negative contact on brush assembly | Contacts oxidised, and current stops flowing to them when heated |

The service life of a starter is approximately 70,000–200,000 km, and to ensure it serves your vehicle for as long as possible, periodical preventative maintenance is required.

When it is necessary to test the starter and repair it correctly, it is recommended to study the technical specifications of the specific model. The main ones are: nominal voltage and power, current consumption, torque generated, and shaft rotation speed.

Frequently Asked Questions About Starter Faults

-

What are the types of starter faults?

Faults can be electrical or mechanical. Electrical causes mainly concern a discharged battery, wiring problems, poorly secured or oxidised terminals. Mechanical ones, which are the most frequent, include:

— worn brushes;

— burnt contact plates;

— worn bushings;

— broken armature or stator windings;

— slipping overrunning clutch;

— jammed helical spline drive on the armature shaft. -

How do I know when to replace the starter?

The starter is generally repairable, but it should be replaced with a new one if repairs have been done repeatedly and the following symptoms reappear:

— upon turning the key, the starter armature spins, but the crankshaft does not;

— the starter continues to run after the engine has started;

— loud grinding is heard during starting;

— on repeated attempts to start, the starter groans, whistles, or even crunches;

— the starter does not engage or only clicks, and there is a distinct smell of burning (burnt winding). -

What could be wrong if the starter doesn't turn?

First, the cause may lie in the battery or poor contact quality. The most frequent causes are:

— weak charge;

— oxidised battery terminals;

— deteriorated/loose contact on the starter;

— short circuit in the starter winding;

— solenoid not working. -

Worn starter brushes – symptoms

You can tell that the brushes are worn by a primary sign – the starter does not activate on the first attempt (clicking is heard, but the starter does not spin, though it may turn over after 5-10 attempts). Sometimes you even have to tap the starter housing a few times to "wake it up". However, be careful with this, as the stator may contain magnets instead of a field winding — tapping can chip the pole magnets.

Also, when brushes are worn, a slight knocking or crackling may be heard. Wear also manifests as a characteristic smell of burning and solenoid clicking, while the starter does not start. -

How to identify worn starter bushings?

If there are traces of the armature rubbing against the stator winding (a distinct contact patch appears), the starter bushings are worn and need changing. If bushings are not changed in time, the starter will begin to heat up, and eventually, the bakelite (used to treat winding wires) will melt. Result: inter-turn short, then short circuit and burnt winding.

-

Why does the starter work intermittently?

If the starter turns over only sometimes, the cause may be the relay (clicks are heard). You can test this option by shorting the starter directly (bypassing the relay). If it starts spinning, the problem is in the relay, the wiring leading to it, or the ignition switch. The starter may also work intermittently if the brushes are worn down.

Additional materials on the topic:

- Starter won't turn over

- 5 main reasons for starter failure. Video

Was this article useful?

Your feedback helps us improve our content.

Related Materials

Discussion (0)

No comments yet!