How to Decode Tyre Markings

For many car owners, decoding tyre markings is a complex task, as most people are unfamiliar with the alphanumeric codes found on the sidewall. However, this information is useful for any driver, as it allows you to purchase tyres that best suit your specific needs—for example, when buying summer or winter tyres. In the guide below, we have gathered and structured the information to present tyre marking designations in an interactive and easy-to-understand format.

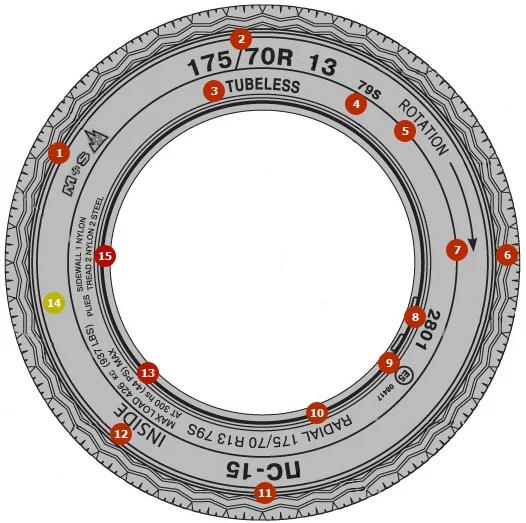

- The inscription M+S and the mountain peak symbol indicate that it is a winter tyre.

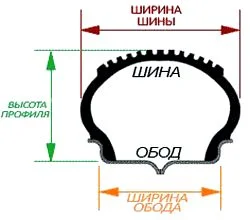

- Tyre size designations. 245 — tyre section width, 45 — aspect ratio (height of the profile as a percentage of the width), R — radial construction, 18 — rim diameter (in inches).

- TUBELESS — indicates a tubeless tyre.

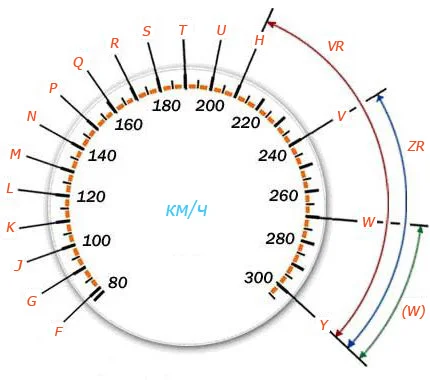

- Maximum load and speed indices. The corresponding tables are provided later in the text. You can consult them below.

- The word Rotation with an arrow indicates the direction in which the tyre must rotate when the vehicle is moving forward.

- TWI — indicates the location of the tread wear indicator.

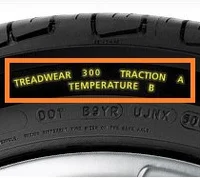

- Temperature, traction, and treadwear indices (UTQG). You will find their detailed description further in the article.

- The number 2801 signifies the date of manufacture — the 28th week of 2001.

- E4 — means the tyre has been approved in the Netherlands and complies with ECE (Economic Commission for Europe) quality standards. The country code is followed by the specific approval numbers. See the table of country codes below.

- RADIAL — indicates a radial tyre construction.

- PS-15 — a code designating the manufacturer or the brand under which the tyre was produced.

- INSIDE — denotes the inner side of the tyre; OUTSIDE — the outer side (for asymmetric tyres).

- MAX LOAD — the maximum allowable load value in absolute units (kg or lbs) at the pressure specified below.

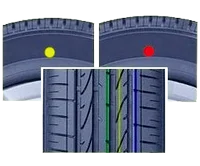

- A yellow dot or triangle indicates the location of the lightest or softest part of the tyre.

- Tyre construction details. In this case, the manufacturer informs us that the tread consists of two layers of nylon, two steel layers, and one nylon layer. The sidewall consists of two layers of nylon.

Main Markings

There are numerous elements in tyre markings. First, let's list the essential ones:

Decoding symbols on tyres

- manufacturer;

- brand or tyre model name;

- tyre size;

- maximum load index;

- speed index;

- application;

- protection level;

- seasonality and operating conditions;

- other information.

Next, we will look in detail at what these "codes" mean and what values they might have.

Manufacturer. Usually, the manufacturer's name is written in large letters so that it is clearly visible. This is done primarily for advertising purposes. Additionally, many manufacturers have a logo designed in a unique style, which they try to feature on all their products. There are a huge number of automotive tyre manufacturers globally, so there is no need to list them all here.

Brand or Model Line. Many manufacturers own several brands under which tyres are produced. Almost all of them make rubber in various lines and models. Within a single line, you can buy a tyre with different sizes and characteristics. This significantly simplifies selection and expands options.

Car tyre dimensions

Tyre Size. This is perhaps the most important marking on car tyres. Let's consider it with a specific example — 195/60R14. In this case, 195 mm is the tyre section width. It is calculated as the distance between the outer boundaries of the sidewalls of an inflated tyre (excluding protective ribs, various markings, and other additional features). The number 60 is the aspect ratio (profile height to width), expressed as a percentage. In this case, 195 × 0.6 = 117 mm. The letter R stands for Radial construction (today, radial tyres are the most common, having almost universally replaced the older diagonal ply type). The last number (in this case, 14) indicates the rim diameter, expressed in inches. If the letter C (Commercial) is added after the diameter, it means the tyre has a reinforced ply rating and can be used on light lorries, vans, or minibuses. In the latter case, the load index of such tyres is written as two numbers. The first indicates the allowable load for a single tyre, the second for a dual (twin) fitment.

For example, a tyre marked 185/75 R16C 104/102S has increased strength and a load index of 104 (900 kg) for single installation, and 102 (850 kg) for dual installation. The maximum allowable speed is 180 km/h (defined by speed index S; we will touch upon load and speed indices later).

For tyres produced in the USA, there is an alternative designation system that differs slightly from the standard one. Let's look at the example — 35 / 12.5 R15 113Q. In this case, the number 35 means the outer diameter of the tyre in inches. And 12.5 is the nominal width in inches. Otherwise, the information is identical to the standard described above. The main difference is the use of inches instead of millimetres.

Table of correspondence between radial passenger car tyres and wheel rim profiles.

| Tyre Designation | 135/80R12 | 155/80R13 | 165/80R13 | 175/80R13 | 165/80R14 | 175/80R16 | 155/70R13 |

| Rim Profile Designation | 4.00B*, 4.50 | 4 1/2J*, 4J, 5J, 5 1/2J | 4 1/2J*, 4J, 5J, 5 1/2J | 4J*, 4 1/2J | 5J*, 4 1/2J | 5J* | 4 1/2J, 4J, 5J |

| Tyre Designation | 165/70R13 | 175/70R13 | 185/70R13 | 175/70R14 | 185/70R14 | 205/70R14 | 185/65R13 |

| Rim Profile Designation | 4 1/2J*, 4J, 5J | 5J, 5 1/2J, 4 1/2J | 6J*, 7J | 5J*, 5 1/2J | 5J*, 5 1/2J | 5 1/2J*, 6J, 6 1/2J | 5 1/2J*, 6J |

Table of correspondence between light truck/van tyres and wheel rim profiles.

| Tyre Designation | 185/80R15C | 215/80R16C | 225/75R16C | 5.90-13C |

| Rim Profile Designation | 5 1/2J*, 5K, 6J | 6J* | 6 1/2J*, 6J, 5 1/2J | 4J*, 4 1/2J |

"*" — recommended rim profile for the given tyre; permissible profiles are not marked.

Maximum Load Index (Load Index). This refers to the maximum mass the tyre can support. This value is encoded as a number, which does not show the mass itself but serves as a cipher. An approximate value can be calculated by dividing the vehicle's gross weight by four. The load index is usually written immediately after the size.

| Load Index | Load, kg | Load Index | Load, kg | Load Index | Load, kg | Load Index | Load, kg | Load Index | Load, kg |

| 62 | 265 | 75 | 387 | 88 | 560 | 101 | 825 | 114 | 1180 |

| 63 | 272 | 76 | 400 | 89 | 580 | 102 | 850 | 115 | 1215 |

| 64 | 280 | 77 | 412 | 90 | 600 | 103 | 875 | 116 | 1250 |

| 65 | 290 | 78 | 425 | 91 | 615 | 104 | 900 | 117 | 1285 |

| 66 | 300 | 79 | 437 | 92 | 630 | 105 | 925 | 118 | 1320 |

| 67 | 307 | 80 | 450 | 93 | 650 | 106 | 950 | 119 | 1360 |

| 68 | 315 | 81 | 462 | 94 | 670 | 107 | 975 | 120 | 1400 |

| 69 | 325 | 82 | 475 | 95 | 690 | 108 | 1000 | 121 | 1450 |

| 70 | 335 | 83 | 487 | 96 | 710 | 109 | 1030 | 122 | 1500 |

| 71 | 345 | 84 | 500 | 97 | 730 | 110 | 1060 | 123 | 1550 |

| 72 | 355 | 85 | 515 | 98 | 750 | 111 | 1090 | 124 | 1600 |

| 73 | 365 | 86 | 530 | 99 | 775 | 112 | 1120 | 125 | 1650 |

| 74 | 375 | 87 | 545 | 100 | 800 | 113 | 1150 | 126 | 1700 |

When studying this information, remember that it refers to the limit load for the tyre itself, without specific reference to the vehicle or operating conditions. Furthermore, do not forget that a tyre should not operate under critical conditions, i.e., at maximum load. For passenger cars, it is advisable not to exceed 80% of these values. For SUVs or 4x4s, the limit should be around 70%. Excessive load not only shortens the tyre's lifespan but is also extremely dangerous due to the risk of a blowout. If this happens at high speed, it can be fatal!

E1 — E48 (usually written in a circle). This indicates the country where the tyre received its ECE (Economic Commission for Europe) approval and the standard number.

| Table of Country Codes for Standardization | |||

|---|---|---|---|

| Code | Country | Code | Country |

| E1 | Germany | E21 | Portugal |

| E2 | France | E22 | Russia |

| E3 | Italy | E23 | Greece |

| E4 | Netherlands | E24 | Ireland |

| E5 | Sweden | E25 | Croatia |

| E6 | Belgium | E26 | Slovenia |

| E7 | Hungary | E27 | Slovakia |

| E8 | Czech Republic | E28 | Belarus |

| E9 | Spain | E29 | Estonia |

| E10 | Serbia | E31 | Bosnia and Herzegovina |

| E11 | United Kingdom | E34 | Bulgaria |

| E12 | Austria | E36 | Lithuania |

| E13 | Luxembourg | E37 | Turkey |

| E14 | Switzerland | E39 | Azerbaijan |

| E15 | Not used | E40 | North Macedonia |

| E16 | Norway | E43 | Japan |

| E17 | Finland | E45 | Australia |

| E18 | Denmark | E46 | Ukraine |

| E19 | Romania | E47 | South Africa |

| E20 | Poland | E48 | New Zealand |

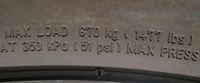

Maximum Load and Maximum Pressure Designation

Maximum Allowable Load (Max Load, measured in kilograms or pounds). This value is analogous to the one above. The difference is that the characteristic is given in absolute values. Pay attention to where the tyre was produced to avoid confusing kilograms with pounds (for reference, 1 pound = 0.4536 kg).

Speed indices and maximum speed values

Speed Index. This information is encoded using letters of the English alphabet. We present another tyre marking table decoding this index. The indicated speed is permitted at maximum load on the tyre. This index is usually listed after the load index.

Maximum Allowable Pressure (Max Pressure). This is one of the most critical pieces of information on passenger tyre markings. Pressure is indicated in kPa or PSI (pounds per square inch, a non-SI unit used in the US and UK). Often, values in both units are found on tyres simultaneously. If only one value is listed, remember that 1 kgf/cm² (technical atmosphere) = 0.98 bar = 14.22 PSI = 98.066 kPa. You can find additional information on the correct tyre pressure for various cars in our other guides.

M+S inscription and winter tyre symbol

M+S Marking (sometimes M&S). This designation is widely used by tyre manufacturers. The letter M stands for Mud, and S for Snow. These designations tell the car owner that the tyre can be used in such conditions. It is worth noting that while often called "winter" tyres, strictly speaking, M+S refers to the tread pattern geometry. For severe winter conditions, look for the "Alpine" symbol (snowflake on a mountain).

Marking by Season and Surface. You may also encounter the following seasonality designations:

One variant of all-season tyre marking

- AS (All Seasons, Any Season). The tyre is suitable for use year-round.

- AGT (All Grip Traction). All-season tyre.

- R+W (Road + Winter). Rubber for use in colder seasons.

- Frost. Indicates winter tyres.

- AW (Any Weather). Suitable for any weather conditions.

- A/T (All Terrain). The tyre is suitable for use on any terrain (on and off-road).

- M/T (Mud Terrain). The tyre is designed for muddy landscapes (off-road).

It is worth adding that some manufacturers illustrate weather properties not with text but with icons. For example, if you see a snowflake, rain, and sun drawn together, it means the tyre is all-weather. A snowflake or mountain peaks (sometimes combined) are used to designate winter tyres. Additionally, some winter models use winter wear indicators (4 mm deep) instead of the standard 1.6 mm ones. Usually, a winter tyre can be distinguished by touch; its surface is softer.

Common designation for all-weather tyres

Rain Tyres. Let's look at how to decode markings for tyres designed for wet conditions. Such tyres are marked with words like Aquatred, Aquacontact, Rain, Water, Aqua. In some cases, an umbrella icon is drawn on the sidewall instead of words.

Tyre Function. Now let's consider the intended application. Letters appearing before the size indicate this:

- P (Passenger). For use on passenger cars (common in US standards).

- LT (Light Truck). For light lorries or vans.

- ST (Special Trailer). For trailers.

- LRO (Low Platform Trailer). For use on low-bed trailers.

- T (Temporary). For temporary use (space-saver spare wheels).

Week and year of manufacture, plus DOT mark

Date of Manufacture. Tyre markings allow you to find the month and year of production. This information is encoded in four small digits enclosed in an oval on the sidewall. The first two digits indicate the week number of the year, and the second two indicate the year itself. For example, marking 1015 tells us the tyre was produced in the 10th week of 2015, i.e., roughly early March.

Temperature, Traction, and Treadwear Indices

Indices (UTQG). Often, especially on tyres targeting the US market, three indices are written after the size:

- Temperature Index (Temperature A, B, C). Indicates how resistant the tyre is to high temperatures and whether it maintains its properties. 'A' is considered the best index.

- Traction Index (Traction AA, A, B, C). The tyre's ability to stop on wet surfaces. 'AA' or 'A' are the best ratings.

- Treadwear. Measured in numbers usually above 100. 100 is the baseline value. The higher the number, the longer the expected tread life compared to the baseline. This parameter is defined according to US standards.

View of the tyre wear indicator

Construction Details. Sometimes, manufacturers list the materials used in the tyre layers. For example, TREAD PLIES: 2 POLYESTER CORD + 2 STEEL CORD + 1 NYLON CORD means the tread consists of two layers of polyester, two layers of steel cord, and one layer of nylon cord.

Wear Indicator. This shows how worn the tyre is and if it's time for replacement. It is usually located at the bottom of a tread groove, very close to the TWID inscription (sometimes TWI or DSI are used). An arrow on the sidewall points to its location.

Studs. On tyres where studs are used, manufacturers indicate the following info:

- AD. Aluminium studs.

- SD. Studs with a carbide core.

- DD. Studs with a rectangular core and diamond face.

- OD. Studs with an oval core.

- MD. Plastic studs with a carbide core.

Coloured Marks. Manufacturers sometimes use coloured markings on their products, specifically white, red, and yellow dots or triangles.

Coloured tyre designations

A red dot or triangle is placed at the stiffest point of the tyre sidewall. If mounting on an alloy wheel, align this with the 'L' mark on the rim (if present). A white dot or triangle indicates the most flexible point on the sidewall. When mounting on an alloy wheel, this should be diametrically opposite the 'L' mark. A yellow triangle indicates the lightest point of the tyre, which should be aligned with the valve stem on the wheel rim.

Occasionally, you may see coloured lines on the tread of a new tyre. These are factory markings that help warehouse workers store tyres with specific characteristics together. For the consumer, these lines confirm that the tyre has not been used.

Puncture Protection Information. Manufacturers use various technologies to protect tyres from cuts and punctures (Run-Flat). Different brands designate them differently. Below is a correspondence table.

| Tyre Manufacturer | Marking | Tyre Manufacturer | Marking |

| Bridgestone | RFT (Run-Flat Tyre) | Michelin | ZP (Zero Pressure) |

| Continental | SSR (Self Supporting Run-Flat) | Pirelli | EUFORI@ or RF |

| Goodyear | EMT (Extended Mobility Technology) or RunOnFlat | Nokian | Run Flat or RF |

| Kumho | RF | Yokohama | RF |

Designation of a tyre with reinforced sidewalls

These technologies allow the car to continue driving with partial or complete pressure loss for 50 to 150 kilometres, provided the speed does not exceed 80 km/h. Additionally, there are markings indicating the presence or absence of rim protection:

- MFS (Maximum Flange Shield). Rim protector.

- FR (Flange Protector, similar to RPB (Rim Protection Bar) or MFS). Tyre with rim protection.

- FB (Flat Base). The tyre does not have a structural element to protect the rim from curb damage.

Visual Lettering Markings. If the manufacturer applies coloured advertising or other designations to the sidewall, the codes are as follows:

- OWL (Outline White Letters). White outline letters on the sidewall.

- BSW (Black Side Wall). Black letters.

- VSB (Vertical Serrated Band).

- RWL. Raised White Letters.

- ORBL (Outlined Raised Black Letters).

- RRBL (Recessed Raised Black Letters).

- WSW. White Side Wall.

- BLK. Black Side Wall.

Additional Information. Manufacturers sometimes include extra info about qualities and characteristics:

- TUBELESS. Indicates a tubeless tyre.

- TUBE TYPE (or TT, sometimes 'Mit Schlauch' on German tyres). Indicates a tyre requiring an inner tube.

"High Ply Rating Tyre"

- PR. Ply Rating. For passenger cars, this is usually 4PR or 6PR. 'Reinforced' usually implies 6 layers. If a tyre has 6PR or 8PR, it can be used on light lorries or vans (Commercial, 8 layers).

- Country of Origin. Usually written as "Made in [Country]".

- Side Designation. Asymmetric tyres will have OUTSIDE (or Side Facing Out) on the outer wall, and INSIDE (or Side Facing Inwards) on the inner wall.

- Left or Right. Directional tyres specific to one side of the vehicle.

- Direction of Rotation. Look for the word Rotation and an arrow indicating forward movement.

Reinforced tyre

- XL (Extra Load). A reinforced tyre capable of carrying higher loads than a standard tyre of the same size.

- Steel. Indicates steel cord in the construction. If missing, textile cord is used. All Steel means steel cord in both the carcass and the breaker belts.

- DOT X0 (Department of Transportation, X0 is the manufacturer code). US quality standard compliance.

- Plies: tread. Composition of the tread layer.

- Sidewall. Composition of the sidewall layer.

- DA or Secunda (stamped). Marks tyres with minor cosmetic defects that do not affect safety or operation.

"Green Tyre" Marking

- Green X, Reduces CO2. Indicates low rolling resistance, reducing fuel consumption and CO2 emissions.

- ND (Non-Directional). Tyre with a non-directional tread pattern.

- NHS (Non-Highway Service). Not for highway use (low speed).

- SAG (Super All Grip). High-traction off-road tyres.

- SUV (Sport Utility Vehicles). Tyres for crossovers and heavy 4x4s.

- REGROOVABLE. Tread depth can be deepened by cutting (common on truck tyres).

- RETREAD. A retreaded tyre.

- Studless. Cannot be studded.

- Studdable. Can be studded.

Marking for studded winter tyres

- Studded. Factory studded tyre.

- National Standards. On locally manufactured tyres, manufacturers may print the specific national standard number (e.g., ISO, BS, or similar local codes) under which the product was made.

Useful Information

Remember that most major global tyre manufacturers have their own specific designations for certain nuances, operating conditions, and technologies. You can verify this information on the official website of the tyre company.

Try to install tyres of not only the same size and construction but also the same model and manufacturer on your vehicle. Despite external similarities, different rubber compounds have different characteristics, which can play a decisive role in critical situations.

Avoid the following situations when mixing tyres on your vehicle:

- low-profile tyres at the front and high-profile at the rear;

- studded tyres at the front and non-studded at the rear;

- new tyres with deep tread at the front and bald tyres at the rear, or vice-versa.

Here is a table with information on recommended tyre size substitutions.

| Tyre Substitution Table | |

|---|---|

| Size of replaced tyre | Substitution option (most suitable option listed first) |

| 135/80R12 | 155/70R12, 155/65R13 |

| 165/70R13 | 185/65R13, 165/65R14, 175/70R13, 185/60R14, 195/50R15 |

| 175/70R13 | 175/65R14, 185/60R14, 185/65R13, 155/R13, 165/70R14, 165/65R14 |

| 175/70R14 | 185/65R14, 195/60R14, 195/55R15 |

| 185/70R14 | 195/65R14, 205/55R15, 195/60R15 |

| 195/65R15 | 215/60R15, 235/55R15, 205/55R16, 215/55R15 |

| 195/70R15 | 205/65R15, 225/60R15, 205/55R16 |

| 205/70R15 | 215/65R15, 235/60R15, 205/65R15, 225/65R15 |

| 205/70R15 | 205/75R15, 215/65R15 |

The data from the table will help you correctly select both the rubber itself and the size that best fits your car. You cannot simply install any tyre on a car; they may not fit, no matter how much you want them to. Note that all tyre sizes approved for a specific vehicle are found on a placard on the front door pillar or sill, along with the manufacturer's recommended tyre pressures.

Conclusion

We have tried to provide the most complete information on how manufacturers encode tyre characteristics. We are confident that you will now be able to easily understand what the markings on car tyres mean. If you encounter designations not covered in this material, we would be happy to see your comments in the discussion.

Was this article useful?

Your feedback helps us improve our content.

Discussion (0)

No comments yet!