How to check a strut top bearing

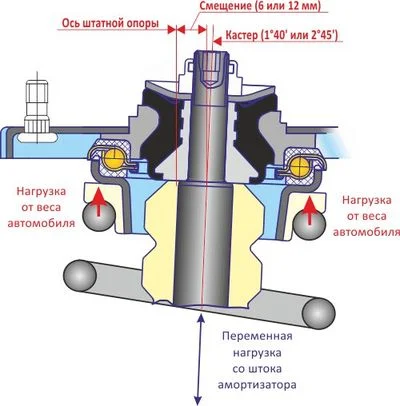

When faults develop in a car's front suspension, one of the first components an owner should inspect is the strut top bearing, located between the suspension strut mount and the upper spring seat. Constant, rapidly changing loads—including impacts from the road—combined with dust and grit, contribute to the wear of the bearing components, eventually causing them to fail. As a result, the bearing develops play, starts to knock or squeak, and the shock absorber piston rod may deviate from its axis.

Strut bearing operation diagram

Ignoring the problem can lead to serious consequences. A worn strut bearing causes wheel alignment issues, deteriorated handling, and accelerated tyre wear. Below, we explain how to perform a check and which manufacturers to choose for a replacement.

Symptoms of a faulty strut bearing

The primary sign of failure that should alert a driver is a knocking sound in the area of the front strut towers (left or right). While other suspension parts can also be sources of knocks and squeaks, diagnosis should often start with the top mount bearing.

Characteristic unpleasant sounds occur when driving on uneven roads, over potholes, during sharp turns, and when the car is heavily loaded. Additionally, handling deteriorates: the steering responds with a delay, feels sluggish, and the car may start to 'wander' on the road.

Causes of failure

The main enemies of the strut bearing are sand, dirt, and water that penetrate inside and wash away the grease, as well as heavy impacts to the suspension strut.

- Natural wear and tear. Road quality directly affects service life: bearings often wear out faster than the manufacturer claims.

- Dirt ingress. The strut bearing often lacks hermetic sealing, so abrasive particles quickly destroy its working surface.

- Aggressive driving style. Hitting bumps and potholes at high speed leads to the destruction of not only the bearing but the entire strut assembly.

- Manufacturing defects or low quality. Cheap alternatives often suffer from poor metal hardening or insufficient lubrication.

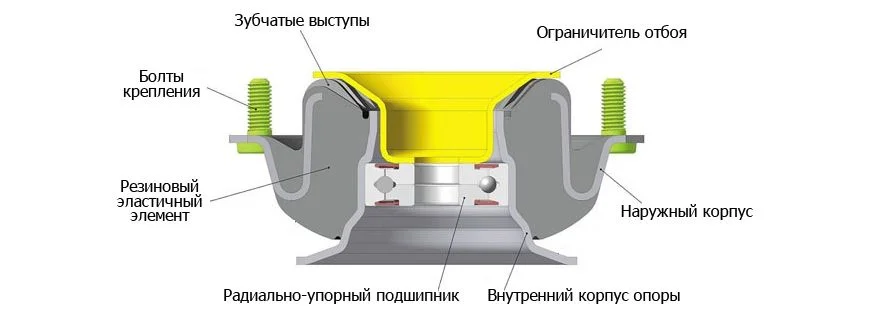

Front strut assembly layout

How to check the strut bearing

You can identify a strut bearing fault yourself using three methods:

- Remove the protective caps under the bonnet and press the top element of the front strut rod (the nut or the mount itself) with your fingers. Rock the car by the wing (fender) in longitudinal and transverse directions. If the bearing is faulty, you will feel play and hear a dull knock. The strut may also move in jerks.

- The most reliable method (requires an assistant). Place your hand on a coil of the front shock absorber spring. Ask your assistant to turn the steering wheel from side to side. If the bearing is worn or seizing, the spring will turn with a jerky motion, emitting a metallic click or grinding sound, which is clearly felt as vibration in your hand.

- Listen to the sound while driving. When driving over speed bumps, making sharp turns, or braking, a metallic crunch or knock may be heard from the wheel arches. The steering may also feel 'vague' or spongy.

The bearing itself is generally not repaired—it is replaced with a new one. It often makes sense to replace them in pairs and renew the rubber strut mounts at the same time.

How to choose strut bearings

Strut bearing

The aftermarket is saturated with offers of varying quality. It is best to stick to original parts (OEM) or proven global brands that often supply assembly lines. Buying the cheapest alternatives is a lottery where there is a high risk of getting a part that will start knocking after just a couple of thousand kilometres.

Based on the experience of car owners and mechanics, the following list of reliable manufacturers can be highlighted:

- SNR (France) — frequently found as original equipment on European makes (Renault, Peugeot, Citroën). Distinguished by a long service life.

- SKF (Sweden) — a world leader in bearing production. Premium segment products.

- FAG / INA (Germany) — part of the Schaeffler Group. High quality, but it is important to beware of counterfeits.

- Koyo (Japan) — an excellent choice for Japanese and Korean vehicles.

When purchasing, always check for branded packaging, holograms, and the quality of the markings on the metal itself. Counterfeits of famous brands are common, and their lifespan is extremely short.

Conclusion

If the bearing seizes, the spring can snap and puncture the tyre, which could lead to a loss of control at speed. Furthermore, a worn bearing disrupts suspension geometry, forcing the driver to constantly correct the steering, and accelerates the wear of shock absorbers and tyres. Do not delay replacement if grinding or knocking sounds appear.

Was this article useful?

Your feedback helps us improve our content.

Related Materials

Discussion (0)

No comments yet!