Alternator faults: signs, causes and diagnostics

The main power sources in a car are the battery and the alternator. A fault in either of them leads to incorrect operation of the on-board electrical system and often makes driving impossible.

The battery and alternator work in an inseparable tandem. Failure of one element inevitably affects the other. For example, an old battery with a short-circuited cell leads to an increase in charging current, which overloads the alternator's diode bridge. Conversely, if the voltage regulator fails, the charging current may increase, leading to overcharging, electrolyte boiling and destruction of the battery plates.

Common alternator faults

- pulley wear or damage;

- carbon brush wear;

- collector (slip ring) wear;

- voltage regulator failure;

- short circuit in the stator winding turns;

- bearing wear or destruction;

- rectifier (diode bridge) damage;

- damage to charging circuit wiring.

Common battery faults

- short circuit of battery electrodes/plates;

- mechanical or chemical damage to plates;

- loss of casing tightness (cracks);

- chemical oxidation of terminals.

The main causes of these faults are:

- gross violations of operating rules;

- expiry of the component's service life;

- manufacturing defects.

The alternator design is more complex than that of a battery, so there are more reasons for its breakdown, and diagnostics are more difficult.

Modern cars are equipped with AC alternators featuring a built-in diode bridge (rectifier) and a voltage regulator. The rectifier converts alternating current into direct current, and the regulator stabilises the voltage (usually within 13.8–14.8 V) regardless of engine speed. Integrated voltage regulators are compact modules often mounted directly on the unit.

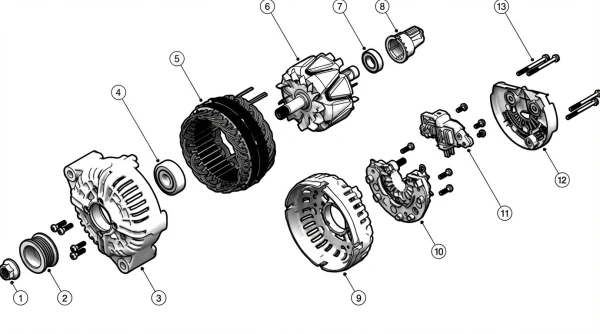

- nut

- pulley

- front cover

- front bearing

- stator

- rotor

- rear bearing

- rear bearing sleeve

- rear cover

- diode bridge (rectifier)

- voltage regulator

- protective cover

- through bolt

Types of faults

Since the alternator is an electromechanical device, faults are divided into two types:

- Mechanical: destruction of the housing or mountings, bearing failure, pressure spring issues, belt drive problems.

- Electrical: winding breaks, diode bridge failure, brush wear, inter-turn short circuits, regulator relay faults.

- Brushes (Wear out most often)

- Bearings (Wear out most often)

- Rectifier unit (Fail less often)

- Voltage regulator (Fail less often)

Often, symptoms pointing to the alternator are caused by other issues. For example, poor contact in a fuse socket or ignition switch can mimic an alternator failure. The battery light staying on constantly might be caused by a faulty relay rather than the alternator itself.

Main signs of alternator failure:

- The battery charge warning light stays on or flickers while the engine is running.

- Rapid battery discharge or overcharge (boiling).

- Dim headlights or a quiet horn while the engine is running.

- Headlight brightness changes in proportion to engine RPM (slight changes when moving from idle are acceptable, but constant flickering is not).

- Unusual sounds (whining, squealing, grinding) coming from the alternator.

Repair kits and spare parts

Eliminating faults often requires replacing individual components. The concept of an "alternator repair kit" on the market is vague: often, sets of bolts and washers are sold under this name, which will not help with electrical repairs.

To restore functionality, specific components usually need replacement:

- brush assembly;

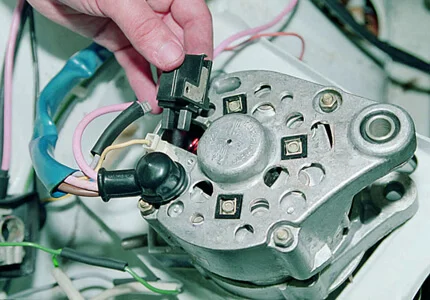

- voltage regulator;

- diode bridge;

- bearings.

Avoid buying "universal" kits. Select parts (brushes, bearings, relays) strictly according to the part number of your alternator or car model.

Fault diagnostics

Important: Never check the alternator on a modern car by disconnecting the battery terminal while the engine is running. The resulting voltage spike can instantly destroy the ECU and other electronics.

Testing is performed only with a multimeter (voltmeter). First, measure the voltage at the battery terminals with the car engine off (normal is ~12.5–12.7 V). Then start the engine and measure again.

Normal charging voltage is 13.8–14.8 V.

- Above normal: overcharging is occurring, the voltage regulator is faulty.

- Below normal: charging is absent or weak (problems with diodes, brushes, windings, or the belt).

Causes of breakdowns

Most often, the cause is simple wear and tear (brushes wear down, bearings reach the end of their life) and contact corrosion.

Other factors:

- low quality of components;

- operation in severe conditions (dirt, road salts, high temperatures);

- ingress of technical fluids (oil, coolant) onto the windings.

DIY inspection

First, check the alternator belt tension and the charging circuit fuse. If the belt is loose, it will slip, making a characteristic squealing sound, and charging will be unstable.

Visual inspection: check the integrity of wires and ensure there are no cracks in the housing. Remove the brush assembly (on many models this can be done without removing the alternator) — the brushes should move freely in their channels and have sufficient length.

Checking bearings: remove the belt and spin the pulley by hand. Rotation should be smooth, without sticking or noise (play is unacceptable). A whining sound during engine operation indicates bearing wear.

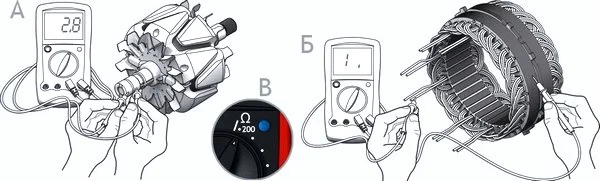

Electrical check of the removed alternator with a multimeter:

- Rotor (field winding): Measure the resistance between the slip rings. The normal range is 1.8 to 5 Ohms. Readings below this indicate a short circuit; higher readings (or infinity) indicate a break.

- Stator: Disconnect the windings from the diode bridge. Resistance between the winding terminals and the housing (earth) should be infinitely high. If the meter shows resistance, there is a short to earth.

- Diode bridge: Switch the multimeter to diode test mode. Each diode should conduct current in only one direction (showing a value of about 400-700 mV one way and infinity the other). If a diode conducts in both directions or not at all, it is faulty.

Repair and troubleshooting

Mechanical issues (noise, vibration) are resolved by replacing bearings, the pulley, or the belt. On cars with high mileage, skimming the slip rings (collector) may be required if deep grooves have formed from the brushes.

The electrical side is more complex. If diagnostics reveal a faulty regulator or diode bridge, these units are replaced with new ones. Rewinding burnt stator or rotor windings is currently not cost-effective — it is simpler and more reliable to buy a new alternator or a factory-refurbished unit.

Causes of low voltage (undercharging):

- loose drive belt;

- poor "earth" contact (engine-body-battery);

- wear of brushes or slip rings;

- voltage regulator failure;

- failure of one or more bridge diodes;

- break or short in the windings;

- excessive load (too much non-standard equipment installed).

Was this article useful?

Your feedback helps us improve our content.

Related Materials

Discussion (0)

No comments yet!