Turbocharger Oil Leaks: Main Causes and Repairs

Oil leaking from a turbocharger can occur for various reasons: from a clogged air filter and crankcase ventilation issues to critical wear of the turbocharger itself. In most cases, the leak is caused by external factors that can be rectified without replacing the expensive component.

Causes of Oil Consumption in Turbos

Before diagnosing, it is important to understand consumption norms. Any turbo consumes a small amount of oil due to evaporation. However, a consumption of 1.5–2.5 litres per 10,000 kilometres, which some sources cite as normal, is a cause for concern for a modern, healthy civilian engine. If you have to top up more than 1 litre between services, you need to find the cause.

Often the problem lies not in a failure of the turbo itself, but in changes in pressure at the intake or exhaust, causing healthy seals (dynamic rings) to let oil pass through.

Blocked Air Filter. The most common cause. If the filter is clogged, excessive vacuum (negative pressure) is created at the compressor inlet. Due to the pressure difference, oil is literally sucked out of the bearing housing into the intake side (compressor housing).

Air Intake Line Issues. If the intake pipe is deformed or blocked, the effect will be similar to a clogged filter — increased resistance at the intake and oil suction from the turbo cartridge.

Intake Leaks. Cracks in the filter housing or pipes downstream lead to the ingress of dust and sand. Abrasives wear down the impeller blades, increase clearances, and quickly destroy the turbo.

Oil Problems. Turbocharged engines are sensitive to lubricant quality and change intervals. Dirty oil cokes the feed and drain channels and causes abrasive wear to the journal bearings. Use only oils approved by the manufacturer (usually synthetic) and change them at least every 7,000–8,000 km.

Oil in the Intercooler. A small amount of oil mist in the pipes is acceptable (from the crankcase ventilation system). But if oil pours out of the intercooler, it is a sign of a leak from the compressor side due to a blocked air filter or oil drain issues.

Oil in the Hot Side (Exhaust). If oil is being driven into the exhaust pipe, the cause is often a restricted oil drain from the turbo (clogged pipe, high crankcase pressure) or total wear of the shaft seals on the turbine wheel side.

Serious Turbocharger Failures:

- Bearing and Shaft Wear. Excessive play develops, the shaft begins to wobble, damaging the seals. Oil starts to pour out heavily. Repair or replacement of the cartridge (CHRA) is required.

- Impeller Damage. Occurs when foreign objects (nuts, sand) enter the intake. Leads to imbalance and destruction of the unit.

Methods for Fixing Leaks

Before replacing the turbo, perform the following checks. In 80% of cases, the problem is solved by eliminating external factors.

- Check the Air Filter. Replace the filter if it is visually dirty. A blocked filter creates a vacuum that pulls oil out of the turbo.

- Intake Revision. Clean the pipes and filter housing of debris. Check them for airtightness. Any air leak bypassing the filter will quickly kill a new turbo with sand.

- Oil Feed and Drain. Check the oil drain pipe (return line). It must be clean, not kinked, without sharp bends or sealant. Oil drains from the turbo by gravity; any obstruction here will force oil to seek an exit through the seals into the exhaust or intake.

- Crankcase Ventilation (Breather). A critical point. If the PCV valve is blocked, excess pressure builds up in the crankcase (and in the turbo drain pipe). The oil has nowhere to drain, and it is forced out through the turbo. Check and, if necessary, replace the ventilation valve.

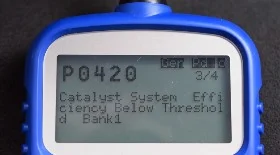

- Catalytic Converter and DPF. If the exhaust is blocked, backpressure is created, which can disrupt the operation of the turbo's dynamic seals.

- Shaft Play. Remove the intake pipe and check the impeller with your fingers. Slight radial play (up and down) is acceptable, but the impeller should not touch the walls. Axial play (in and out) is unacceptable. If there is excessive play, the turbo needs repair.

Rare and Specific Cases

Mechanical Damage. The entry of a foreign object (bolt, rag) into the intake leads to the destruction of the blades. In such cases, repair is not viable; replacement of the unit (cartridge or complete turbo) is required.

Loose Fasteners. On some turbo models (including commercial vehicles), the bolts securing the compressor or turbine housing to the cartridge can loosen due to vibration. This may look like a leak at the joint. Check the bolt tightness.

High Oil Level. If the engine oil level is above the MAX mark, the crankshaft can foam the oil, and the drain from the turbo will be restricted (the drain hole may end up below the oil level). Correct the oil level.

Piston Group Wear. With severe wear of the piston group (blow-by), gas breakthrough into the crankcase is so great that the ventilation system cannot cope. Excess pressure in the crankcase backs up the oil drain from the turbo, causing a leak.

EGR Valve Blanking. There is an opinion that blanking off the EGR valve helps keep the intake clean. However, this changes the engine's operating modes and requires proper software remapping. Simply disabling the EGR does not eliminate the cause of the turbo oil leak if the shaft itself is worn.

Was this article useful?

Your feedback helps us improve our content.

Related Materials

Discussion (0)

No comments yet!