Vacuum Leaks

When a car hesitates for a split second during a sharp start, or in some cases even stalls, there is a 99% chance it is a vacuum leak. This is because excess air entering the engine cylinders causes a sudden leaning of the mixture and, as a result, ignition difficulties. The engine misfires and may stall at idle.

You can read more details in this article.

Symptoms of a vacuum leak

The symptoms of an engine vacuum leak are usually quite clear:

- Hesitant start in the mornings.

- Unstable idle – idling speed constantly fluctuates and drops below 1000 rpm; the engine may stall. On cars with a carburettor engine, the mixture quality and quantity screws become insignificant for adjusting the idle regime because air is bypassing the idle channel.

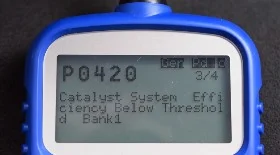

- Loss of power – in the intake tract on systems with a MAF (Mass Air Flow) sensor — low idle speed; on systems with a MAP sensor (Manifold Absolute Pressure), conversely — increased idle speed, lambda sensor errors, lean mixture, misfires.

- Increased fuel consumption – to move off and keep driving, you need to constantly maintain high revs, while staying in a lower gear for longer.

Vacuum leak locations

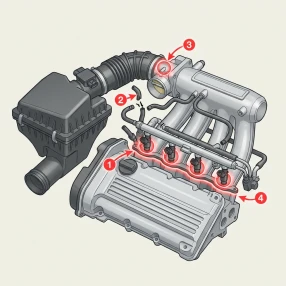

The main places where air leaks can occur include:

- intake manifold gasket;

- throttle body gasket;

- section of the hose from the air filter to the throttle assembly;

- injector sealing rings (O-rings);

- brake servo (vacuum booster);

- vacuum hoses;

- evaporative emission (EVAP) canister purge valve;

- idle air control valve (if equipped).

It is worth considering air leak locations on carburettor engines separately — there are no electronics there, and air can only be drawn in at the brake servo or somewhere within the carburettor.

Leak locations (Carburettor)

- At the fuel mixture quality screw.

- Behind the gasket under the carburettor – areas with soot are a sure sign.

- Through a poorly seating throttle plate.

- Through the throttle shafts.

- Breaches in the integrity of the throttle damper diaphragms, economiser, or choke.

Air ingress in a diesel fuel system

In a diesel engine fuel system, aeration usually occurs due to a leaking joint in the low-pressure fuel lines (from the tank to the filter and from the filter to the high-pressure fuel pump).

Cause of leaks on a diesel car

Air intake in a non-hermetic fuel system happens because atmospheric pressure is higher than the pressure created when the pump is drawing diesel from the tank. It is almost impossible to detect such a depressurisation by a fuel leak.

On modern diesel engines, the problem of air ingress into the fuel system is encountered much more frequently than on old-style diesels. This is all due to changes in the design of fuel hose connections, as they used to be brass, but now they make plastic quick-release connectors, which have a limited service life.

Plastic, as a result of vibrations, tends to wear down, and rubber sealing rings wear out. This problem manifests itself particularly clearly in winter on cars with a mileage of over 150,000 km.

The main reasons for air ingress are often as follows:

- old hoses and loose clamps;

- damaged fuel pipes;

- loss of seal at the fuel filter connection;

- breach of tightness in the return line;

- compromised seal of the drive shaft, the fuel control lever axis, or in the injection pump cover.

In most cases, it is simply the ageing of rubber seals, and the fuel system can become aerated if any of the branches are damaged, both the feed and the return.

Signs of air ingress

The most frequent and common sign – the car stops starting quickly in the mornings or after a long standstill; you have to crank the starter for a long time (while doing so, a little smoke comes out of the exhaust — this indicates fuel is entering the cylinders). A sign of a major leak is not only difficult starting, but the engine also begins to stall and misfire while driving.

Such vehicle behaviour is due to the fact that the injection pump cannot pass the foam through itself quickly enough except at high revs, whilst at idle it cannot cope with the large amount of air in the fuel chamber. Determining whether the problem with the diesel engine's operation is specifically related to air ingress can be done by replacing standard pipes with transparent ones.

How to find a leak in a diesel fuel system

Air can be drawn in at a connection, in a damaged pipe, or even in the tank. You can find it by the process of elimination, or by applying pressure to the system.

The best and most reliable method is to find the leak by elimination: connect the diesel supply to each section of the fuel system not from the tank, but from a jerry can. Check sequentially — connect directly to the injection pump first, then connect before the sedimenter, and so on.

A faster and simpler option to determine the leak location is to apply pressure to the tank. Then, at the point where air is being sucked in, either hissing will appear, or the connection will start to weep.

Vacuum leak in the intake manifold

The essence of a vacuum leak in the intake tract is that excess air, unaccounted for by the MAF or MAP sensor, enters the engine along with the fuel, leading to a lean air-fuel mixture in the cylinders. This, in turn, contributes to incorrect engine operation.

Cause of the air leak

- Mechanical impact.

- Overheating (affects the elasticity of gaskets and sealant).

- Excessive use of carburettor cleaning agents (greatly softens sealant and gaskets).

It is most problematic to find a leak location in the area of the gasket between the cylinder head and the intake manifold.

How to find a manifold air leak

On petrol engines, air unaccounted for by sensors enters the intake manifold through loose connections or damaged air ducts, worn injector seals, as well as through brake servo vacuum hoses.

We have dealt with the standard leak locations; now it is worth finding out how to search for a vacuum leak. There are several main search methods for this.

The simplest way to check if there is a vacuum leak in the intake tract after the flow meter is to unscrew the air intake pipe together with the sensor from the air filter housing and start the engine. Then cover the assembly with the sensor with your hand and watch the reaction — if everything is normal, the engine should stall, firmly compressing the pipe after the air sensor. Otherwise, this will not happen, and you will most likely hear hissing. If you cannot find the air leak using this method, then you need to continue searching using other available means.

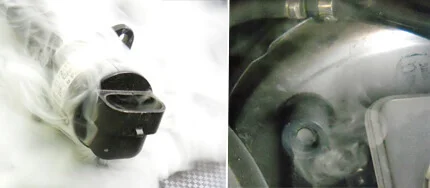

Often, leaks are sought either by pinching hoses or by spraying probable spots with combustible mixtures, such as: petrol, carb cleaner, or WD-40. But the most effective method for finding the place where unmetered air is entering is the use of a smoke generator.

Searching for a vacuum leak

As a rule, idle problems, as well as the appearance of a lean mixture error, happen only with a strong leak. A minor leak can be determined by observing fuel trims at idle and higher revs.

Checking for leaks by pinching hoses

To find the place where excess air is seeping in, start the engine and let it run for a while; meanwhile, listen carefully and try to hear hissing. If you fail to spot it, pinch the hoses that go to the intake manifold (from the fuel pressure regulator, brake servo, etc.). When changes in engine operation are observed after pinching and releasing, it means the fault is in that section.

Also, sometimes, a compressed air search method is used. To do this, with the engine off, close off the pipe from the filter and pump air through any tube, having previously treated the entire intake tract with a soapy solution.

How to detect a leak by spraying

Spraying connection points with some combustible mixture while the engine is running effectively helps to establish the place where air is leaking into the engine. This can be either ordinary petrol or a cleaner. A change in engine RPM (dropping or increasing) will indicate that you have found the place where it is sucking in air. You need to draw the combustible mixture into a small syringe and spray a thin stream onto all places where there might be a leak. After all, when petrol or another combustible liquid hits the place where the seal is broken, it immediately seeps into the combustion chamber in the form of vapour, which leads to a jump or drop in revs.

When searching for leaks, it is worth spraying onto:

- The rubber pipe from the flow meter to the idle air control valve and from the IAC to the rocker cover.

- Connections of the intake manifold with the cylinder head (where the gasket is located).

- The connection of the receiver and the throttle pipe.

- Injector seals.

- All rubber hoses at clamp connection points (intake boot, etc.).

Checking for leaks with a smoke generator

Few people have a smoke generator lying around in the garage, so this method of finding system leaks is mainly used at service centres. However, if the leak could not be found using the methods discussed above in garage conditions, you can make a primitive smoke generator, although a standard one also has a simple design. Smoke is pumped into any opening in the intake tract, and then begins to seep through the gaps.

Was this article useful?

Your feedback helps us improve our content.

Related Materials

Discussion (0)

No comments yet!