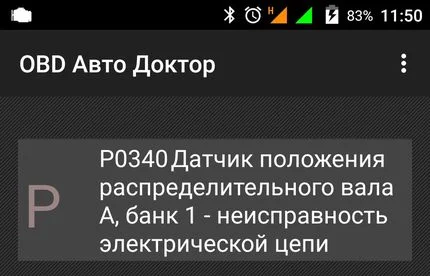

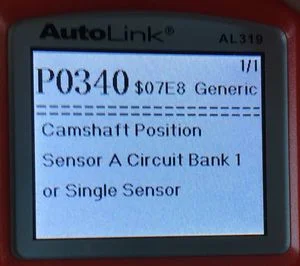

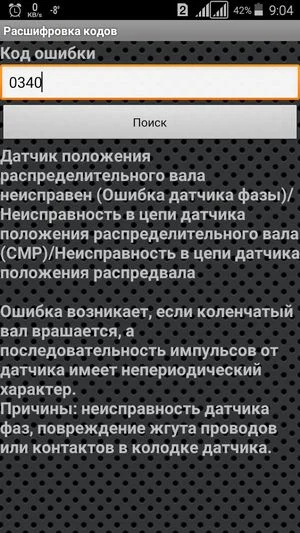

P0340 - Camshaft Position Sensor Error

Error P0340 is defined as a Camshaft Position Sensor A Circuit malfunction. It can arise for various reasons: failure of the camshaft sensor itself, faults in its wiring, or issues with the Engine Control Unit (ECU). The error itself is not critical, and the car can still be driven when it appears. However, it causes certain inconveniences such as increased fuel consumption, reduced power, and other symptoms. Eliminating the causes of error code P0340 is not difficult, and most car owners can handle it.

Operation of the CMP Sensor

First, it is necessary to define what the Camshaft Position Sensor (often abbreviated as CMP) is, its purpose, and its location. The main function of this device is to determine the position of the camshaft at a specific moment in time. This information is transmitted to the electronic engine control unit (ECU) so that it can programmatically calculate the fuel injection timing for each injector. This ensures what is known as phased injection.

If its operation is disrupted, the control unit automatically switches to an emergency mode, providing batch (pairwise-parallel) injection instead of phased injection. This leads to excessive fuel consumption and a loss of engine power.

To address code P0340, it is also important to know the sensor's location on the engine. This is relevant because when this error occurs, additional diagnostics of the CMP and/or its wiring are often required. On 8-valve engines, the sensor is typically located at the end of the cylinder head, closer to the first cylinder. On 16-valve engines, it is similarly installed on the cylinder head, in immediate proximity to the first cylinder.

Its close proximity to the first cylinder is due to the fact that on petrol engines, the sensor detects the position of that cylinder's piston at Top Dead Center (TDC). On diesel engines, the position of all pistons is monitored.

Symptoms of the Error

There are several indirect signs indicating problems with the camshaft position sensor or its wiring. The situations described below may also point to other breakdowns, so if they occur, additional diagnostics with an error scanner (for example, a standard ELM 327 or similar) are needed. However, it is more convenient to use the Rokodil ScanX Pro diagnostic scanner.

Rokodil ScanX Pro

So, when sensor error P0340 occurs, the following may happen:

- Engine starting problems. Often, error P0340 results in the car simply refusing to start. This can happen with both a cold and a warm engine. More commonly, however, it manifests as a longer cranking time required to start the engine. Naturally, this negatively affects the condition of the car's battery and the electrical system as a whole.

- Unstable idle speed. In some cases, the car may simply stall at idle, requiring the driver to manually maintain engine operation by pressing the accelerator pedal.

- Engine misfiring. Misfires occur in the cylinders, leading to a loss of power and a change in the sound of the engine.

- Reduced dynamic performance. The car accelerates poorly and gains revs slowly. There may be "hesitation" from the pedal—meaning acceleration begins a few seconds after pressing the accelerator. The car may also struggle when driving uphill, especially if loaded.

- Fuel consumption increases by 10...20%. This situation arises because the ECU switches to an emergency fuel supply mode (batch injection). Consequently, all the benefits of phased injection are nullified.

- The Check Engine light illuminates on the dashboard. Whenever this light activates, an error scan should be performed. If the symptoms described above are not observed, but the scanner still reports code P0340, check the ECU for a false positive. Simply clear this information from its memory and see if it reappears.

It is worth noting that the listed changes in vehicle behaviour are not as drastic for petrol engines. The loss of power and increase in fuel consumption are not excessively high. The main inconvenience is that the car starts more poorly, requiring longer cranking.

However, for cars equipped with LPG (Liquefied Petroleum Gas) systems, the problems described above can manifest fully. Power loss and increased consumption will be significant. Another issue awaits owners of cars with modern LPG systems, specifically 4th generation kits.

These systems have their own electronic control unit. When the P0340 phase sensor error occurs, operational parameters will constantly be thrown off. Because of this, the gas equipment will firstly need constant recalibration, and secondly, despite adjustments, it will still operate in a sub-optimal mode, consuming more fuel, causing power loss, stalling, and so on.

Conditions for Error P0340 Formation

It should be noted immediately that these conditions may differ across various ECUs and vehicles. However, generally, for the P0340 error signal to form, the following factors are usually required:

- No signals received from the camshaft sensor for more than 5 seconds of starter rotation;

- No signals received from the camshaft sensor to the ECU at engine speeds of 600 rpm or higher.

On some vehicles, this error is not formed in a single drive cycle, but over three. In this case, diagnosis may be more difficult.

Causes of the Error

There are three main causes for engine error P0340:

- Damage to the camshaft sensor wiring. Specifically, a break in the wiring. Typically, the CMP has three wires: power, earth, and signal. Due to mechanical damage, they can wear through, stopping the signal. This most often happens at the terminals or contacts (the connector plug attaching to the sensor or ECU). Another possibility is insulation damage, causing a short to the body or between wires. The result is incorrect data being sent to the ECU.

- Damage to the camshaft sensor. The CMP is a fairly simple and reliable device that rarely fails. However, when error code P0340 appears, it makes sense to check the camshaft sensor.

- Incorrect ECU operation. This is a fairly rare case, as a partial failure of the electronic control unit would result in not just P0340, but many other errors. However, this is possible, for example, if the software was reflashed prior to the error appearing (e.g., during engine tuning, LPG installation, etc.). Consequently, if there were glitches during the flashing procedure or the software itself triggered faults, ECU malfunction is possible. Even more rarely, the sensor may be installed askew, or the unit may have mechanical damage (e.g., after an accident).

Sometimes, the cause of error P0340 is incorrect sensor installation. This is rare since there is usually only one mounting position. It is possible the fastening is not tight enough (low torque, causing vibration while driving) or there is a large gap between the sensitive part of the sensor and the reluctor ring (the tooth on the indicator wheel located on the camshaft).

How to Resolve Error P0340

The methods for eliminating the faults causing error P0340 (camshaft position sensor circuit malfunction) depend on the root cause and the specific car model—for example, Nissan, Ford, Chevrolet, Opel, Toyota, or Lada (specifically VAZ 2114). However, the general inspection algorithm is as follows:

- Use an error scanner to check the ECU memory for error P0340 and any others. If only one error is found (or related ones like P0342, P0343), try to reset it as mentioned above. Clear them using software or by disconnecting the negative battery terminal for 10...20 seconds. If the error disappears after starting the engine, it was a false alarm from the sensor or ECU. If the error reappears (read the code again), continue with further diagnostics and repair.

- Check the latch that ensures firm contact of the connector plug to the sensor housing. In some situations, it may be broken, leading to a loss of contact between all or individual wires and the sensor pins.

- Check the quality of the sensor installation in its seat. Specifically, check the torque of the fastening bolt (usually a 10mm bolt or similar, depending on the engine). Ensure that the sensor installed is the correct one for that specific engine. Sensors can differ not only in mounting but also in model, geometric shape, and size. An incorrect sensor element won't detect the passing reluctor ring, leading to a lack of signals to the ECU. If the sensor is incorrect, buy a new camshaft sensor and replace it.

- Visually inspect the condition of contacts and terminals in the electrical circuit. In some cases, oxidation (rust) occurs on critical terminals, reducing contact quality. This happens due to moisture exposure and/or age. If oxidation is found, remove it by thoroughly wiping the contacts. Special electrical contact cleaners can be used for stubborn dirt.

- Using a multimeter set to continuity or resistance mode, verify the integrity of the wires running from the ECU to the camshaft sensor. Usually, there are three wires. Besides checking wire continuity, check the insulation resistance between them in pairs, and between each wire and the car body (earth). In the latter case, the earth wire will naturally have continuity with the body. During this check, place the multimeter probes on the contacts of the corresponding connectors.

CMP Sensor Check Diagram

- When checking resistance, you must know exactly which pin on the connector does what. For example, on Lada models (like the VAZ-2114), two types of camshaft sensors are used. They have different pinouts. On one type, contact "A" is earth, "B" is signal, and "C" is power (+). On the other, "A" is earth, "B" is power, and "C" is signal. Usually, the other end of the power wire comes from a control relay. For similar sensors on other cars, consult the specific documentation (wiring diagrams).

- If the wire check reveals defects (breaks, damaged insulation), perform a visual inspection to locate the damage. Pay attention to bends and kinks where wires change shape and can rub through due to vibration. Also check if wires pass through areas accumulating moisture or technical fluids (like oil). Insulation can degrade in these places over time. If the damage site cannot be found, replace the camshaft position sensor wiring completely. Use special flexible automotive wires with the appropriate cross-section.

- If the wiring and connector are fine, check the condition of the sensor itself. If the situation allows, replace the sensor with a known working one. Note that there are many poor-quality sensors currently on the market. It is better to choose original sensors according to the car's documentation and order them from official manufacturer representatives. This may be more expensive, but it pays off, as low-quality sensors often fail and require repurchasing and reinstallation.

- If there are no problems with the camshaft sensor, check the normal operation of the electronic control unit. However, it is not recommended to do this yourself, as it is a complex and critical part of the vehicle. Seek help at a garage where there are specialists and additional diagnostic equipment.

Finally, it is worth noting that when detecting camshaft sensor faults, it makes sense to check the crankshaft sensor as well, since these shafts work in sync. If there is no signal from the camshaft sensor, the ECU uses signals from the crankshaft sensor. Check the ECU memory for errors related to the CKP (Crankshaft Position Sensor), such as P0335, and inspect its mechanical condition and wiring if possible (similarly to the CMP).

Conclusion

Error P0340 is not a critical error, and the car can still be driven when it is stored in the engine management system memory. However, it leads to power loss, fluctuating idle speeds, and increased fuel consumption. This is especially relevant for cars equipped with LPG systems using gas as fuel.

Therefore, it is better not to drive with this error for long, as it will cause significant inconvenience to the driver. Ideally, perform diagnostics and repairs as soon as possible, especially since they are not complicated and can be handled by most car enthusiasts.

Was this article useful?

Your feedback helps us improve our content.

Discussion (0)

No comments yet!