How to Check Engine Oil Quality

Engine oil quality directly affects engine performance, service life, fuel consumption, dynamic characteristics, and the amount of lubricant lost to burn-off. All quality indicators of engine oil can only be determined through complex laboratory analysis. However, the most critical signs—indicating that the lubricant needs urgent changing or that you have purchased a counterfeit—can be checked independently.

How to Check Oil Quality

There are a number of simple recommendations for evaluating new engine oil.

Appearance of the Canister and Label

Nowadays, alongside licensed oils, there are many counterfeits in shops. This applies to almost all lubricants in the mid-to-high price range (e.g., Mobil, Shell, Castrol, Total, Liqui Moly, and others). Manufacturers attempt to protect their products as much as possible. The latest trend is online verification using codes, QR codes, or via the manufacturer's website. There is no universal recommendation here, as every manufacturer addresses this issue in their own way.

However, when buying, you should inspect the quality of the canister and the label itself. Naturally, it must contain operational information about the oil inside (viscosity, API and ACEA standards, manufacturer approvals, etc.).

If the font on the label is low quality, applied at an angle, or peels off easily, you are likely looking at a counterfeit product and should refrain from buying it.

Detecting Mechanical Impurities

Quality control of engine oil (relevant for checking for gross impurities in obvious fakes) can be performed using a magnet and/or two glass slides. To do this, take a small amount (about 20–30 grams) of the test oil, place a standard small magnet in it, and let it stand for a few minutes. If the oil contains many ferromagnetic particles, most will stick to the magnet. You will be able to see them visually or feel them by touch. If there is a lot of such debris, the oil is of poor quality and should not be used. In high-quality factory oil, this check will show nothing.

Another method is using glass slides. Place 2–3 drops of oil on one piece of glass, then rub it over the surface using the second piece. If you hear a metallic squeak or crunch during rubbing, or worse, feel mechanical impurities, refuse to use it.

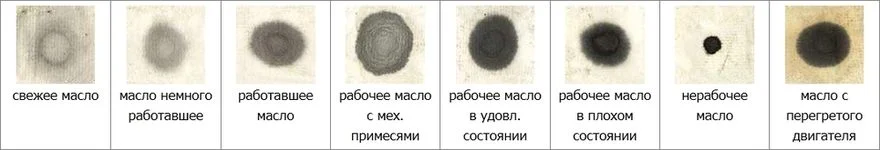

Checking Oil Quality on Paper

Another very simple test involves placing a sheet of clean paper at an angle of 30–45° and applying a couple of drops of the test oil to it. Part of it will be absorbed into the paper, while the rest will flow down the surface. You need to look closely at this trail.

The oil should not be very thick or extremely dark (like tar or sludge). There should be no small black dots in the trail, which indicate mechanical impurities. Also, there should be no separate dark spots; the oil trail must be uniform.

If the oil is dark but sufficiently fluid and clean, it is likely still usable and of reasonably good quality. The fact is, any oil begins to darken after just a few dozen kilometres of driving, which is normal (detergent additives are working).

Home Tests

You can also conduct tests with a small amount of purchased oil, especially if you doubt its quality for any reason. For example, place a small amount (100–150 grams) in a glass beaker or flask and leave it for a couple of days. If the oil is poor quality, it is highly likely to separate into fractions. That is, the heavy parts will settle at the bottom, and the light ones will be at the top. Naturally, such oil should not be used in an engine.

You can also freeze a small amount of oil in a freezer or outside if the temperature is very low. This will give an approximate understanding of its low-temperature characteristics. This is particularly relevant for cheap (or counterfeit) oils.

Viscosity can be approximately checked at home using a funnel with a narrow neck (about 1-2 mm). Take an identical amount of new oil (with the same stated viscosity) and lubricant from the sump. Pour each oil into a DRY funnel one by one. Using a watch (stopwatch), calculate how many drops of the first and second oil drip through in the same period. If these values differ significantly, it is advisable to change the oil in the sump.

Indirect confirmation that oil has degraded is a burnt smell. Especially if it contains many impurities. When such an aspect is identified, additional checks must be carried out, and if necessary, the lubricant replaced. An unpleasant burnt smell can also appear if the oil level in the sump is low, so check this indicator simultaneously.

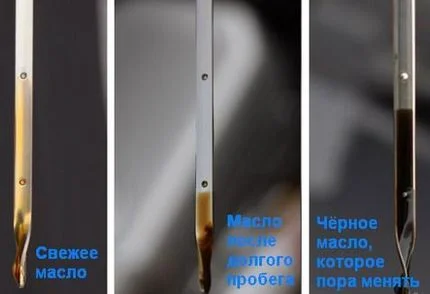

Another "DIY" test involves the dipstick. The algorithm is as follows:

- warm the engine to operating temperature (or skip this step if already done);

- switch off the engine and open the bonnet;

- take a cloth, remove the oil dipstick, and carefully wipe it dry;

- reinsert the dipstick into its tube and remove it again;

- visually assess how the oil drop forms on the dipstick and whether it forms at all.

If the drop has a medium consistency (neither too runny nor too thick), the oil is still quite usable. However, if instead of forming a drop, the oil simply runs down the surface of the dipstick (and especially if it is very dark), such oil is subject to immediate replacement.

Price-Quality Ratio

A ratio of a low price to a "premium" brand can also be an indirect sign that sellers are trying to shift counterfeit goods. No self-respecting oil manufacturer will significantly lower the price of their products without global promotions, so do not give in to the persuasion of unscrupulous sellers.

Try to buy engine oils in proven shops that have agreements with official representatives (dealers) of lubricant manufacturers.

Blotter Spot Test

The most common method for determining the quality of working oil is the blotter spot test (or drop test). It was invented by SHELL, and with it, you can quickly check the condition of the oil using just a single drop.

Using the spot test, you can not only determine the quality of the engine oil but also assess the following parameters:

- engine oil properties;

- approximate condition of the engine;

- determine when to change the oil in the car's engine.

Algorithm for Performing a Test Sample

How do you perform a spot test? Follow this algorithm:

- Warm the engine to operating temperature (approximately to +50…+60°C is sufficient to avoid burning yourself when taking the sample).

- Prepare a clean white sheet of paper in advance (a standard A4 sheet folded in two or four layers, or filter paper, will work).

- Open the oil filler cap or remove the dipstick, and place one or two drops on the sheet of paper.

- Wait 15...20 minutes for the oil to absorb thoroughly into the paper.

Assessment of engine oil quality is based on the shape and appearance of the resulting oil spot.

How to Determine Oil Quality by Spot Appearance

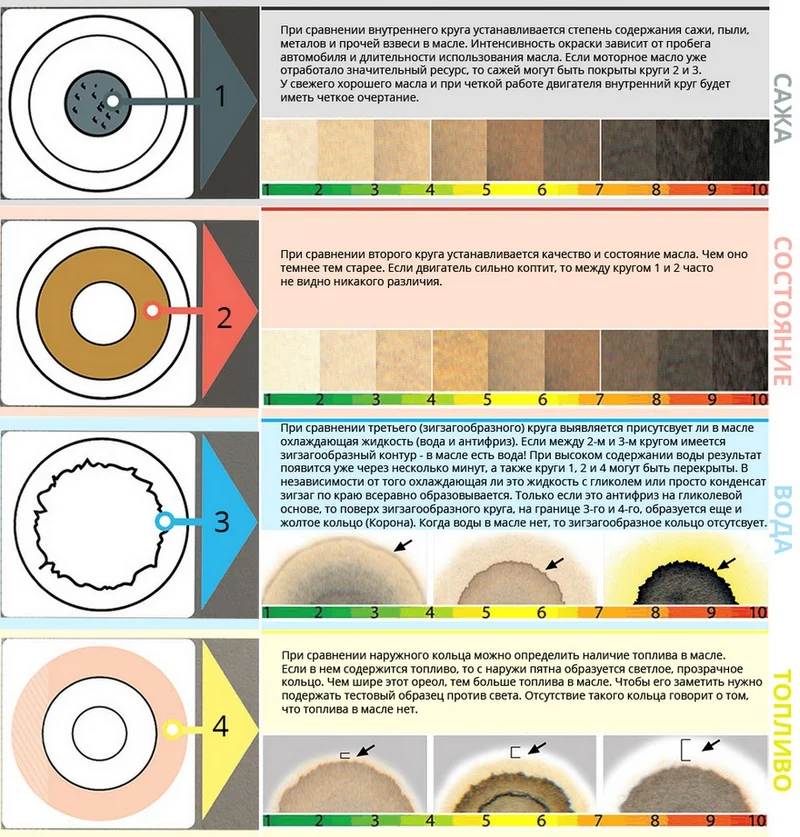

First, pay attention to the colour of the four separate zones formed within the boundaries of the spot.

- The central part of the spot (core) is the most important! If the oil is old, soot particles and mechanical impurities are present here. Due to natural causes, they cannot be absorbed into the paper. Typically, the central part of the spot is darker than the rest.

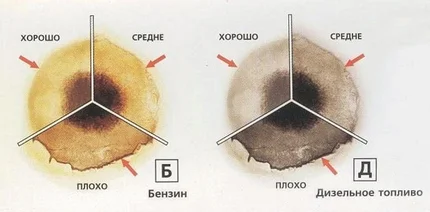

- The second part (edge zone) is oil that has absorbed into the paper but has no heavy impurities. The darker the ring, the older the oil. In diesel engines, the oil will be darker. Also, if a diesel engine smokes heavily, the boundary between the first and second zones is often absent in the spot test; that is, the colour changes gradually.

- The third zone (diffusion zone), further from the centre, can indicate the presence of water. Its presence is undesirable. If there is no water, the edges of the zone will be smooth. If water is present, the edges will be jagged.

- The fourth zone (ring of clean oil) indicates the presence of fuel in the oil. In healthy engines, this zone should not exist or be minimal.

The presence of even a small amount of water in the oil can lead to a deterioration of the oil's protective properties and a change in its viscosity.

Using the drop method, you can also find out how good the oil's dispersant properties are. This indicator is expressed in arbitrary units and calculated using the formula: Ds = 1 — (d2/d3)², where d2 is the diameter of the second zone of the oil spot, and d3 is the third. It is better to measure in millimetres for convenience.

It is considered that the oil possesses satisfactory dispersant properties if the Ds value is not lower than 0.3. Otherwise, the oil requires urgent replacement. Specialists recommend conducting a spot test of engine oil every 1,500–2,000 kilometres.

The test result is often compared with reference scales (where the condition is assigned a score from 1 to 9). In the absence of a colour scale, you can refer to the verbal description in the table below:

| Score (approx) | Condition Deciphering | Operation Recommendations |

|---|---|---|

| 1, 2, 3 (Good) | The core is light or grey, edges are smooth. No dirt or metal particles in the oil | Engine operation is permitted |

| 4, 5, 6 (Average) | The core darkens, zone boundaries blur. Oil contains a moderate amount of wear products | Engine operation is permitted with periodic oil quality checks |

| 7, 8, 9 (Bad) | The spot is black, uniform, without clear zones. Impurity content exceeds the norm | Engine operation is not recommended, oil change needed |

Remember that colour changes do not always indicate a critical change in characteristics. For example, if your car has an LPG (gas) system installed, the oil may not turn black for a long time and keep a light shade even with significant mileage. But this does not mean it can be used forever—additives still wear out, so it must be changed according to the schedule.

Improved Spot Test Method

The classic method of performing a spot test was described above. Ready-made kits also exist (e.g., MOTORcheckUP), where instead of a regular sheet of paper, a special paper "filter" with a reference scale for comparison is provided.

In some modern engines, mechanical dipsticks have been replaced by electronic ones. Consequently, the car owner is deprived of the opportunity to take an oil sample independently (if there is no separate filler neck or access). Such cars have both an electronic level and a special oil quality and condition sensor.

The principle of the oil quality sensor is based on monitoring changes in the oil's dielectric constant, which changes depending on oxidation and the amount of impurities. In such cases, one has to rely on electronics or visit a service centre.

Some manufacturers (e.g., Liqui Moly, Castrol in certain series) add pigments that glow under ultraviolet light to the lubricant composition. In this case, authenticity can be checked using a UV torch.

Portable Pocket Oil Analyser

Modern technical capabilities allow oil quality to be determined not only "by eye" but also with the help of additional gadgets—portable oil analysers.

The procedure for working with them involves placing a small amount of lubricant on the device's working sensor. Using built-in algorithms, the analyser determines the condition of the composition. Of course, it will not replace a full laboratory chemical analysis, but it is sufficient for a driver to get a general picture.

Popular devices (like Lubricheck) often work as interferometers and can assess:

- presence of soot and impurities;

- degree of oxidation;

- presence of water or antifreeze;

- total acid number (TAN) and total base number (TBN);

- dielectric constant.

The simplest and cheapest models show the quality of the tested engine oil in points (for example, on a 10-point scale), where 10 is new oil, and 1 requires immediate replacement.

Was this article useful?

Your feedback helps us improve our content.

Related Materials

Discussion (0)

No comments yet!